Under the EU’s Single-Use Plastics Directive, bottlers and beverage producers have until 2024 to make arrangements for applying tethered caps to their plastic containers. Although this deadline seems far off still, Michael Eschenlohr and his colleagues at Krones LCS are already hard at work implementing the directive. “The first bottling lines are already being changed over and scheduled to resume operation before the end of this year,” explains Michael Eschenlohr. The advantages of making timely preparations for the new caps are quite obvious for him: “As it is, the EU Directive affects a great number of companies, lines, systems and products. If all those concerned jolt into action at the last minute, there will be supply bottlenecks for preforms and closures, and delays in order processing,” he warns. “Our aim is to make sure that the change-over entails no risks and as little outlay as possible for our customers. So we are pleased about every inquiry that comes our way now – no matter whether it asks for a specific change-over job or just some general advice.”

Exceedingly few beverage producers are eagerly anticipating the upcoming obligation to fit plastic containers in the EU with tethered caps. And that’s precisely why it makes sense to actively address it now. Any company that takes steps early can make up for the relevant outlay by simultaneously saving costs elsewhere.

Shorter neck finish, less material

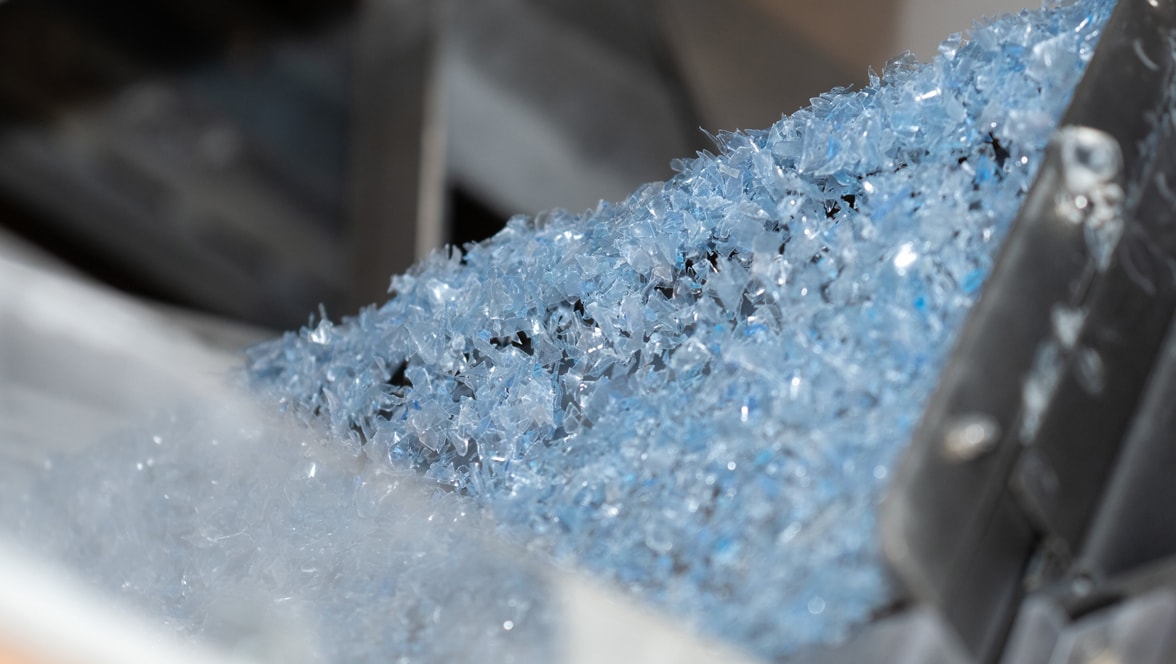

The team at Krones is taking these opportunities to show how the change-over can be instrumental in reducing plastics consumption. At first glance, that may sound paradoxical. After all, one of the most frequently voiced criticisms of the EU Directive is that mandatory use of tethered caps (for which more plastic is required) would undermine the trend towards lightweighting packaging. While this is basically true in regard to the new cap, it also allows for quite a lot of material to be saved elsewhere. That’s because bottles featuring a PCO 1881 neck finish, hitherto the commonly used variant for CSD bottles, can easily be changed over to the shorter GME 30.40 version, which is likewise suitable for tethered caps. “And this can be done without any further bottle design changes. Below the neck ring, everything remains the same,” emphasises Michael Eschenlohr.

The new neck finish is two millimetres shorter and therefore weighs almost one gram less than the previous version. The likewise shorter cap makes for another 0.4-gram weight reduction per cap. On a line that produces 40,000 containers per hour and runs 6,000 operating hours a year, the material thus saved adds up to more than 331 tons. So for all those on whom the tethered-caps obligation is still weighing heavily, this approach can quite literally lighten their load.

“Particularly for companies that have to change their closures anyway, the obvious option is to handle this all in one go, together with the change to a shorter neck finish. In this way, the line change-over pays for itself, so to speak,” says a gratified Michael Eschenlohr. And the geographical range is by no means limited to the EU alone, quite the contrary: The question of how packaging can be designed for more resource-economy and enhanced sustainability is on the mind of everybody working in this sector. So it can safely be assumed that GME 30.40 will become the new standard for CSD containers.

Shorter neck finish for tethered caps: GME 30.40

- Outer diameter: 26.6 millimetres

- Inner diameter: 21.74 millimetres

- Height: approx. 15 millimetres

- Weight: approx. 2.61 grams

Suitable for:

- Bottle sizes of up to three litres

- Heavy carbonation

- All climatic conditions

At the same time, Michael Eschenlohr emphasises that changing over to a shorter neck finish is just one of many opportunities for slimlining containers. “Sustainability is one of the most important trends in the packaging market, and in our view the most sensible one, too. That’s why we offer a lot of additional options for achieving lasting material savings – both in primary and secondary packaging. My colleagues and I will be pleased to provide customised advice at any time.”

Find your inspiration right here

Sustainable packaging is a major focus of our research and development work. To learn more about the projects the Krones experts are currently working on, just watch the videos provided under the following link:

Free download

Read more about tethered caps and the EU Directive 2019/904 “Single-Use Plastics (SUP)” in our whitepaper.