First stop is at our neighbours’, the French: On March 17th, France imposed stringent stay-at-home rules, the so-called "confinement", at our French site though it was still possible to continue working – while observing strict hygiene and safety requirements, of course. Since the service engineers' accommodations were at times located in the so-called "red zone" (a region with particularly high infection rates and even more stringent restrictions), the most urgent task was to secure the service engineers to be lodged and catered during their deployments. Most of the hotels remained closed, but still all colleagues could be accommodated: Either in one of the few hotels that continued to open their doors to business travellers or in an Airbnb flat.

Alongside France, Italy is also one of the European countries particularly hit by the coronavirus pandemic. However, at our subsidiary Kosme in Roverbella only one single employee has fallen ill to date. And since this person – like all others who were able to do so – had been working from home the whole time, there were no infection chains within the company. The restrictions during the lockdown in Italy were very stringent, that’s why our subsidiary System Logistics suspended production for three weeks and Kosme did not resume operations until the beginning of May. Nevertheless, both companies were able to provide continuous support in the event of urgent inquiries or problems – with telephone and remote support requests particularly increased. Fortunately, the existing support team has also been boosted by colleagues who have returned from the global construction sites due to the travel restrictions.

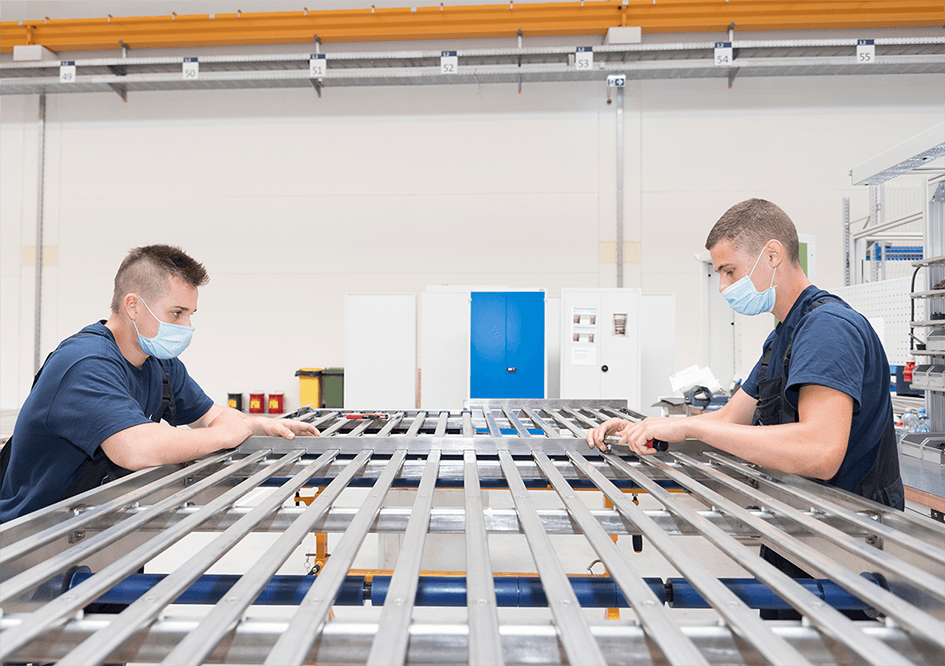

Among other countries, the travel restrictions also left their mark in Hungary: Almost 80 employees who were temporarily located in Germany for training purposes returned to Hungary, as did some engineers from other countries. However, this almost represented a blessing in disguise for the ramp-up of our plant in Debrecen. Although the ongoing learnings and trainings were interrupted, the Hungarian colleagues were able to put into practice what they had already learned. Thus, full manpower was put into further advancing the rollout of production and assembly areas in Debrecen.

A little further up north, at our UK site in Bolton, our colleagues also successfully turned the crisis into an opportunity: while some orders had to be postponed, the colleagues used the time gained to develop new business strategies for the LCS business and responded quickly to customers who were experiencing a technical problem. Since the lockdown has started to be loosened, the colleagues in Bolton have been doing all they can to reschedule cancelled orders and resume work on new machine projects.

Now we are approaching our last stop in Europe: Russia. In no other country in Europe as many people are infected by coronavirus as in Russia – and our Russian branch finds itself in the epicenter of coronavirus in the area around Moscow. Fortunately, the Krones site was able to continue business operations nonetheless – thanks to measures such as mobile working, the compulsory wearing of masks, social distancing, and even the provision of personal protective equipment for those employees who cannot work from home. Here the travel restrictions were also noticeable with German engineers unable to enter the country. But the local fitters did a great job, so that all service projects were completed right on time.

Decentralised service structure pays off

A closer look at the Asia/Pacific Region reveals that this kind of decentralised service structure has paid off here as well. Between Pakistan and New Zealand, Sri Lanka and Japan, there are only a handful of small countries in which Krones is without a local service presence, so urgent service calls could be covered with local personnel. But there are also countries like Bangladesh, Cambodia and India with strict stay-at-home regulations that did not even permit service calls. To bridge the period of underutilisation employees in the region were offered alternative programmes like online training on the one hand; on the other hand Krones decided to take internal measures such as reducing overtime and asking employees to take annual leaves. Since the availability of state aid is limited in these regions, Krones is making every effort to support its employees with these measures.

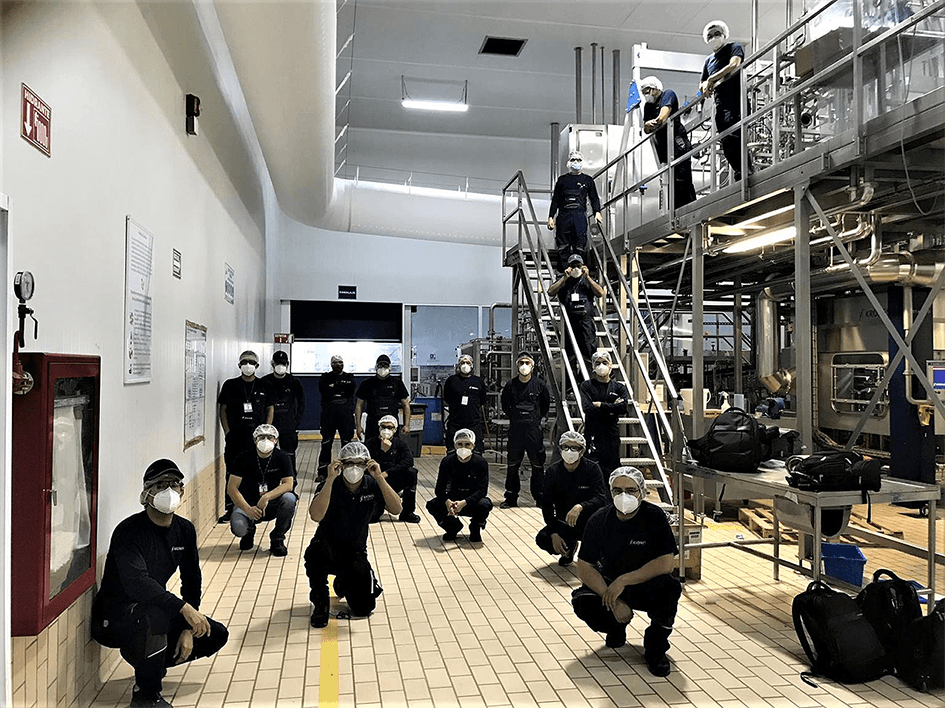

The journey continues with a detour overseas to Latin America: From as soon as May, South America has become the new corona hotspot, with Brazil being among the most affected countries. Our center in São Paolo began to introduce a raft of safety and hygiene precautions just a short while after the major outbreak of the coronavirus pandemic in Europe in mid-March. Thanks to these early precautions, as well as the team spirit and great commitment, the colleagues were able to maintain business operations and continue to support the customers even in these very difficult times.

Finally, we shall pay a visit to China. At our site in Taicang, new ‘normal’ working habits have now developed since the country was the first in the world to feel the full effects of the coronavirus pandemic. After the government extended the traditional week of celebrations for Chinese New Year by three days across the whole country at the beginning of February, all of production in Taicang remained shut down for another week. Production and assembly then restarted on 10th February, but only employees who were symptom-free were allowed to enter the factory premises. At the beginning of March, the office workers also returned from mobile working, but the new ‘normal’ working habits are subject to strict safeguarding measures: a strict requirement for face masks to be worn throughout the whole site (also in individual workplaces), strict adherence to minimum social distances (also during meals and smoking breaks) and fever measurements are the order of the day. If an employee has a measured temperature of 37.5 °C or above, he or she is not permitted to access the site and must instead immediately go to a doctor. Last but not least: In mid-February, Krones also made a donation of the equivalent of 125.000 euros (1 million Chinese Yuan) as an immediate measure to support the badly affected region of Wuhan, where the money was spent on urgently needed medical equipment.

And with that we have come to the end of this little trip. Unfortunately, the sad truth that the coronavirus pandemic has the entire world in its grip is once again confirmed here. But in this context we at Krones have also seen just how valuable cooperation with our international subsidiaries can be: Through experience gained from colleagues in regions where the pandemic had already shown its immense impact, it was possible to act more quickly and competently at locations in regions that had not yet been affected. As a result, measures to contain the virus in the workplace could be taken at an early stage. And on top of that we learned that teamwork and commitment can help us make the best out of the crisis – fortunately, that works worldwide as well.