Beck's, Corona, and Budweiser are enjoyed around the world. They all come from Anheuser-Busch InBev, the world’s biggest brewing group, which produces around one-third of the world’s beer. The group’s portfolio encompasses 630 brands, made in 260 breweries. The Belgian conglomerate employs more than 170,000 people in over 150 countries – including South Africa.

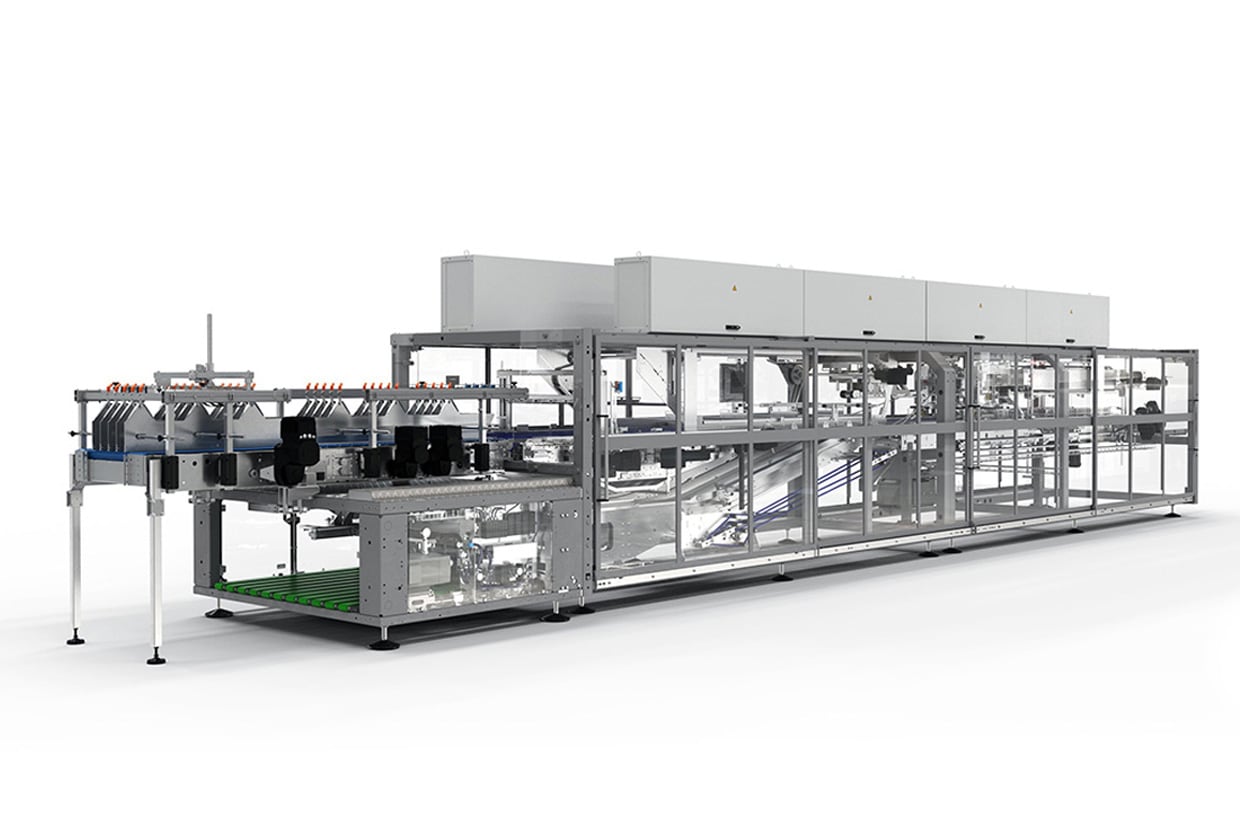

AB InBev operates seven breweries here, including the Pretoria South African Breweries (SAB) site with almost 900 employees. This plant mainly produces the South African beer brand Castle Lite and the Mexican beer Corona, together adding up to some 8.5 million hectoliters each year. To boost production of Corona especially, the company has added a non-returnable glass line from Krones. “We chose Krones because of the good relationship, compatibility with current equipment and reliability standards”, says packaging manager Theo Govender.