The Bischofshof brewery in Regensburg has been making beer for more than 370 years. In 1649, then-Prince-Bishop Wilhelm Graf von Wartenberg established the brewery directly adjacent to the city's iconic St. Peter's Cathedral.

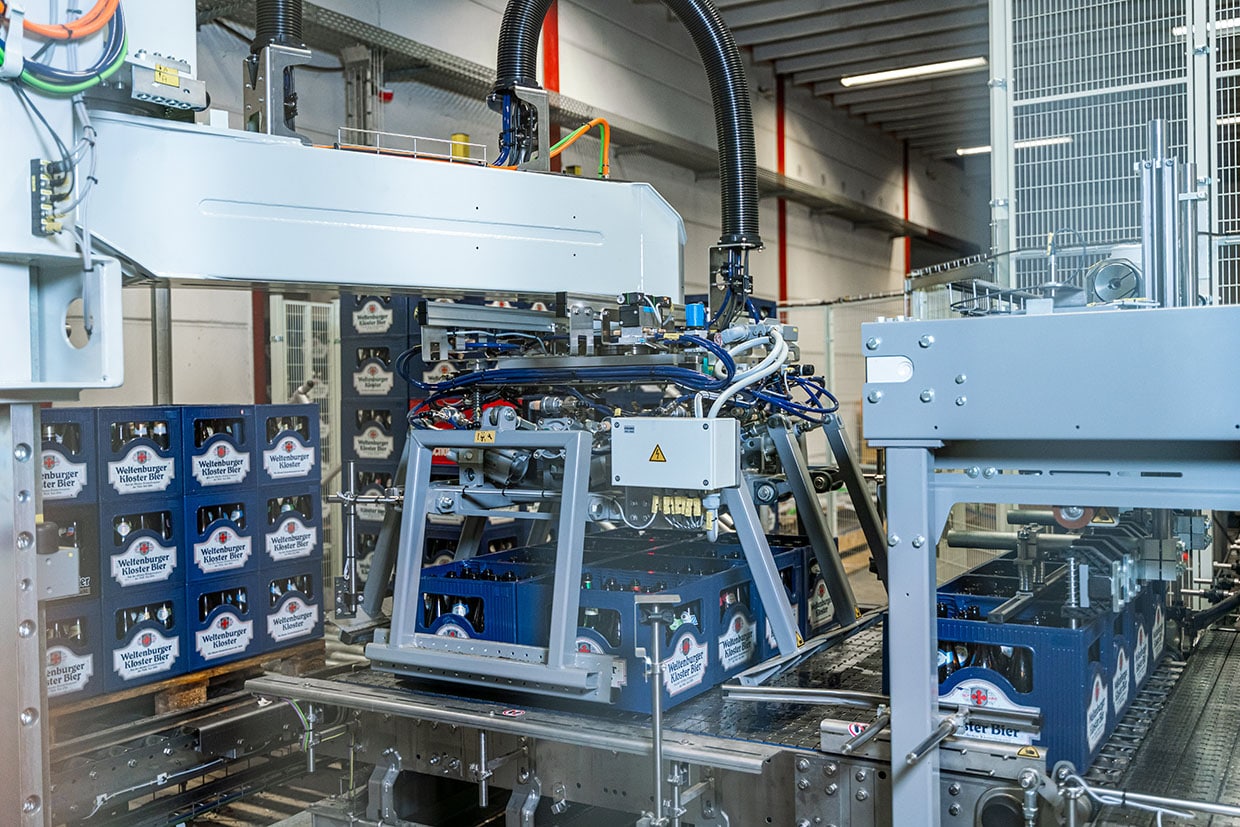

At the start of the 20th century, a lack of space and the risk of fire so close to the cathedral prompted the brewery's move outside the city center to its current location in the Margaretenau district. Besides the Bischofshof beers, the location has since 1973 also been filling the beers produced by the world's oldest monastic brewery, Weltenburger Klosterbrauerei.

"The Bischofshof brewery has not only undergone but driven constant change over the centuries – from societal transformation right through to the production of its beers. This openness allowed the brewery to embrace and implement innovation while at the same time maintaining tradition. And that is exactly what safeguards a company's future," says Susanne Horn, the brewery's managing director, of Bischofshof's path into the 21st century. "It helps that we make one of the best products ever: beer."

Brauerei Bischofshof