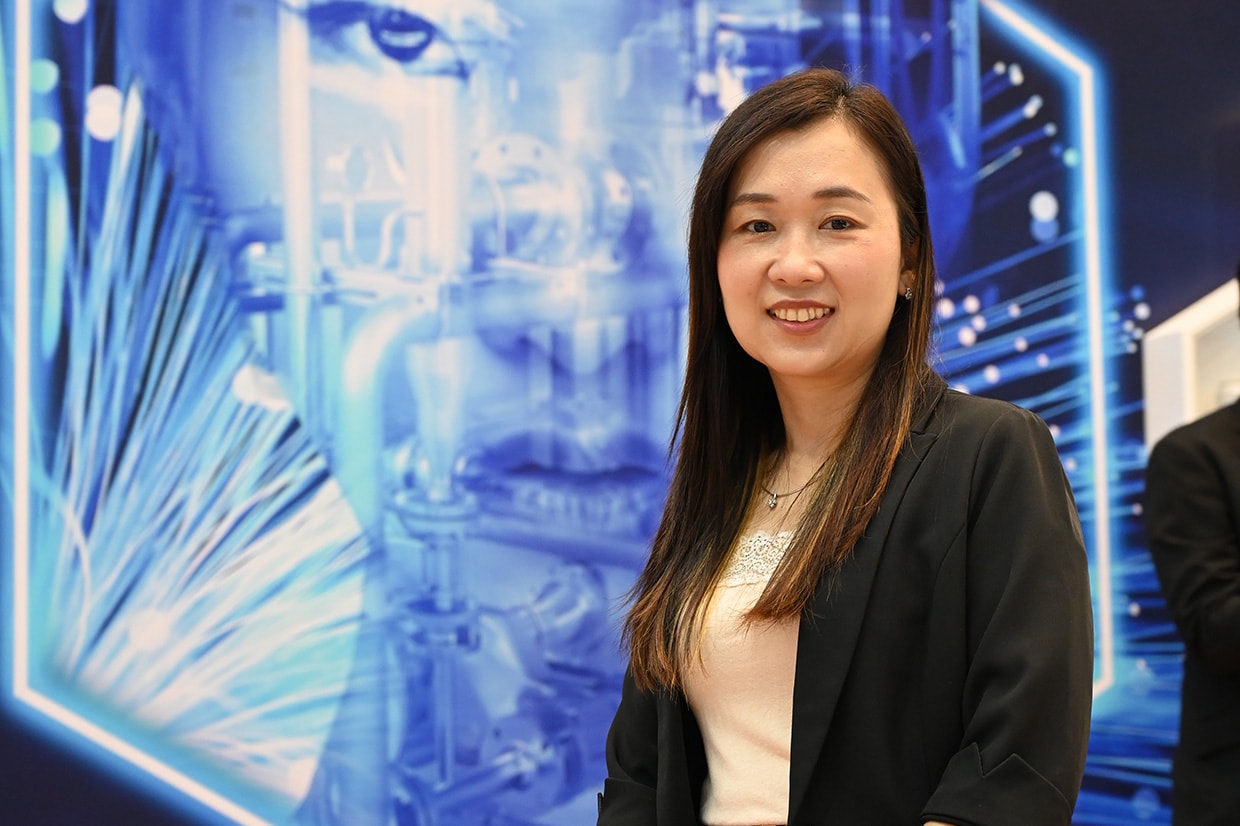

Over the course of four days, visitors got updates on Krones’ technologies, shared insights, grew their networks, and talked about future business. Regis Herve, Head of Sales for the Southeast Asia region, summarizes the show in one sentence: “For Krones, this event was not only a great opportunity to meet and connect with various industry players, but also a great time to share insights and personally discuss exciting developments with our customers.”

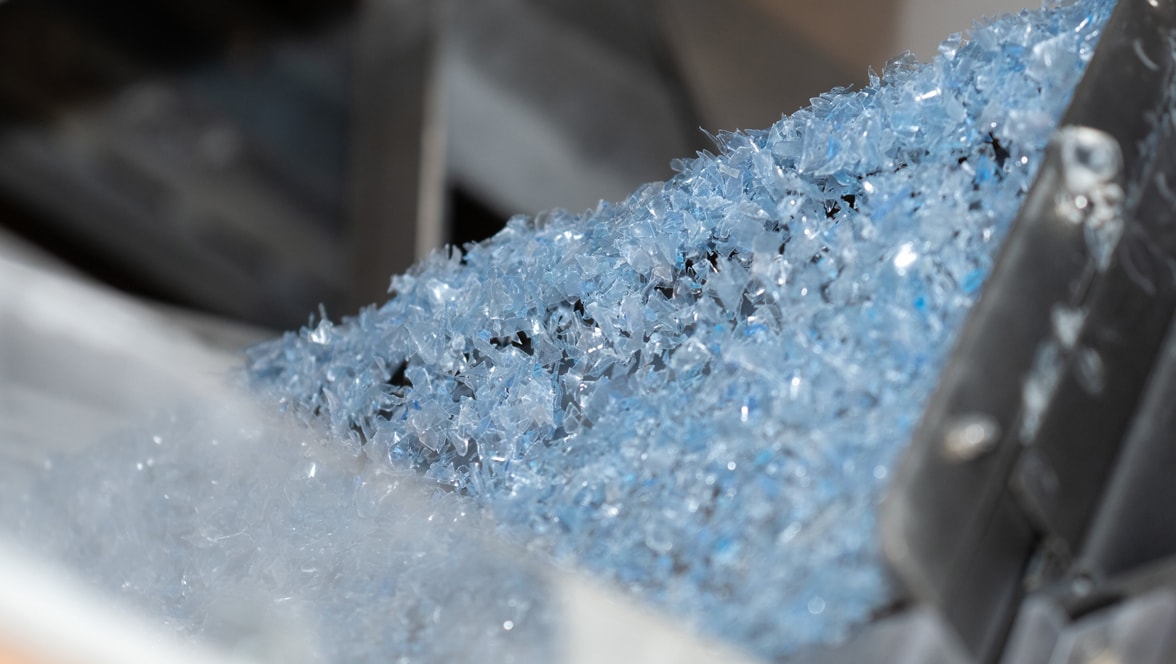

At this year’s ProPak, Krones showcased its expertise in complete line solutions and Lifecycle Service for the food and beverage industry. Placing a special focus on high-performance equipment on the one hand and service on the other, we also revealed an innovative concept for revolutionizing stock-keeping capacities using 3D printing.