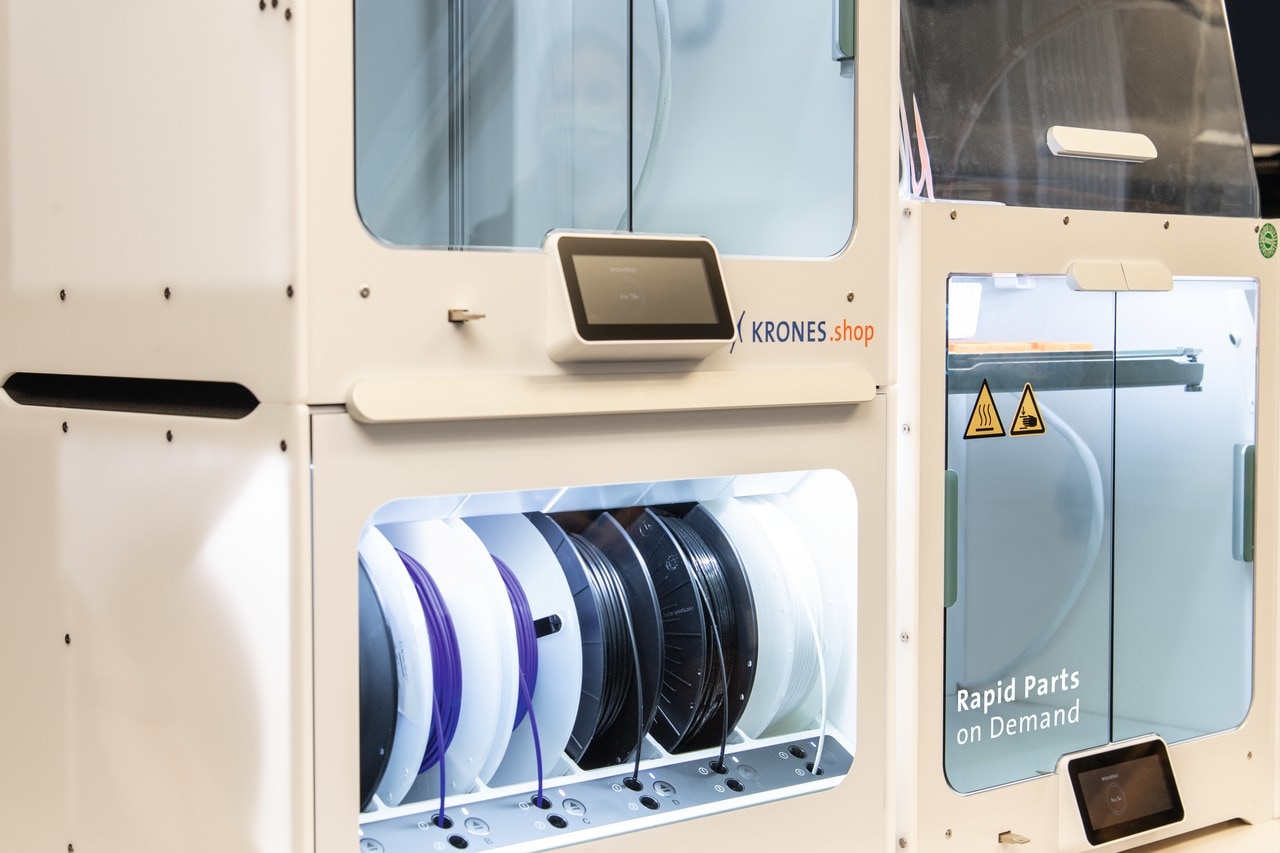

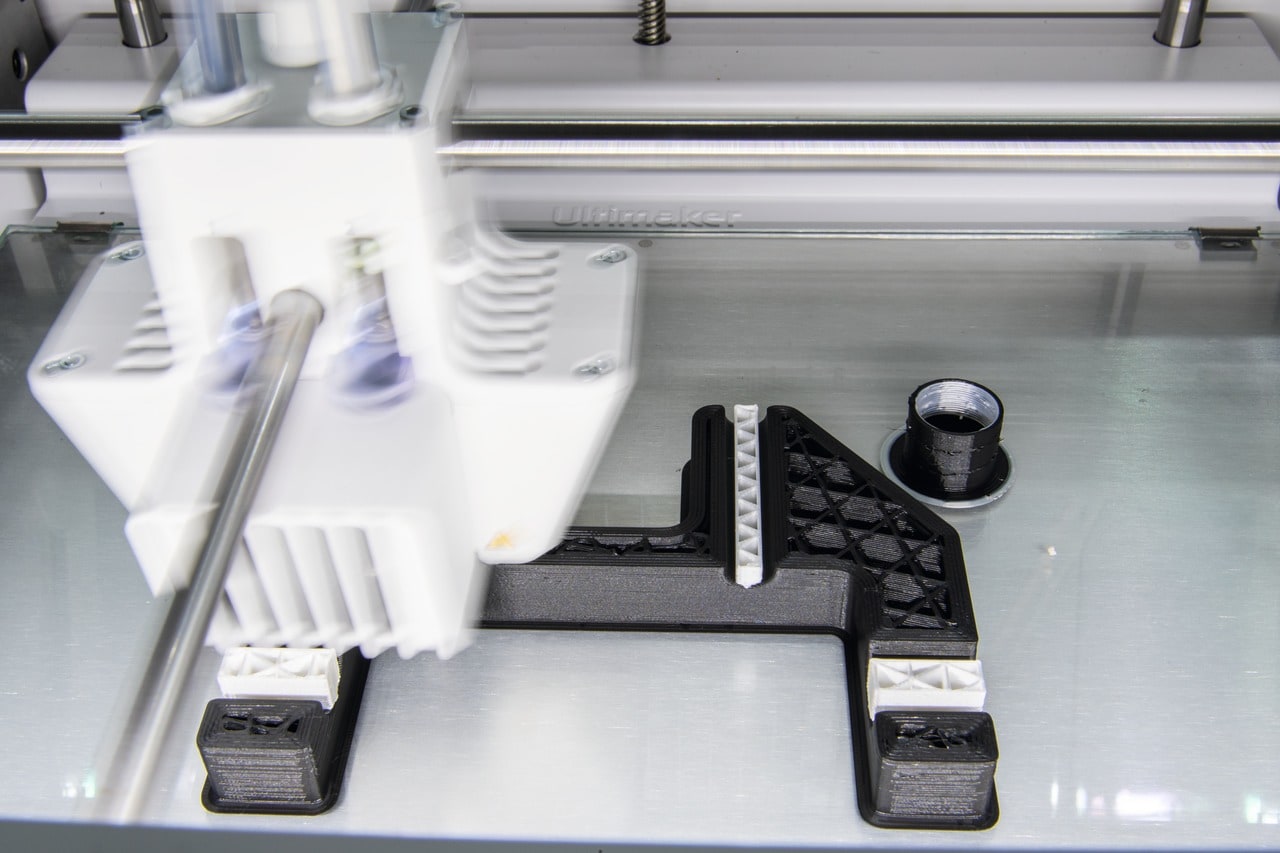

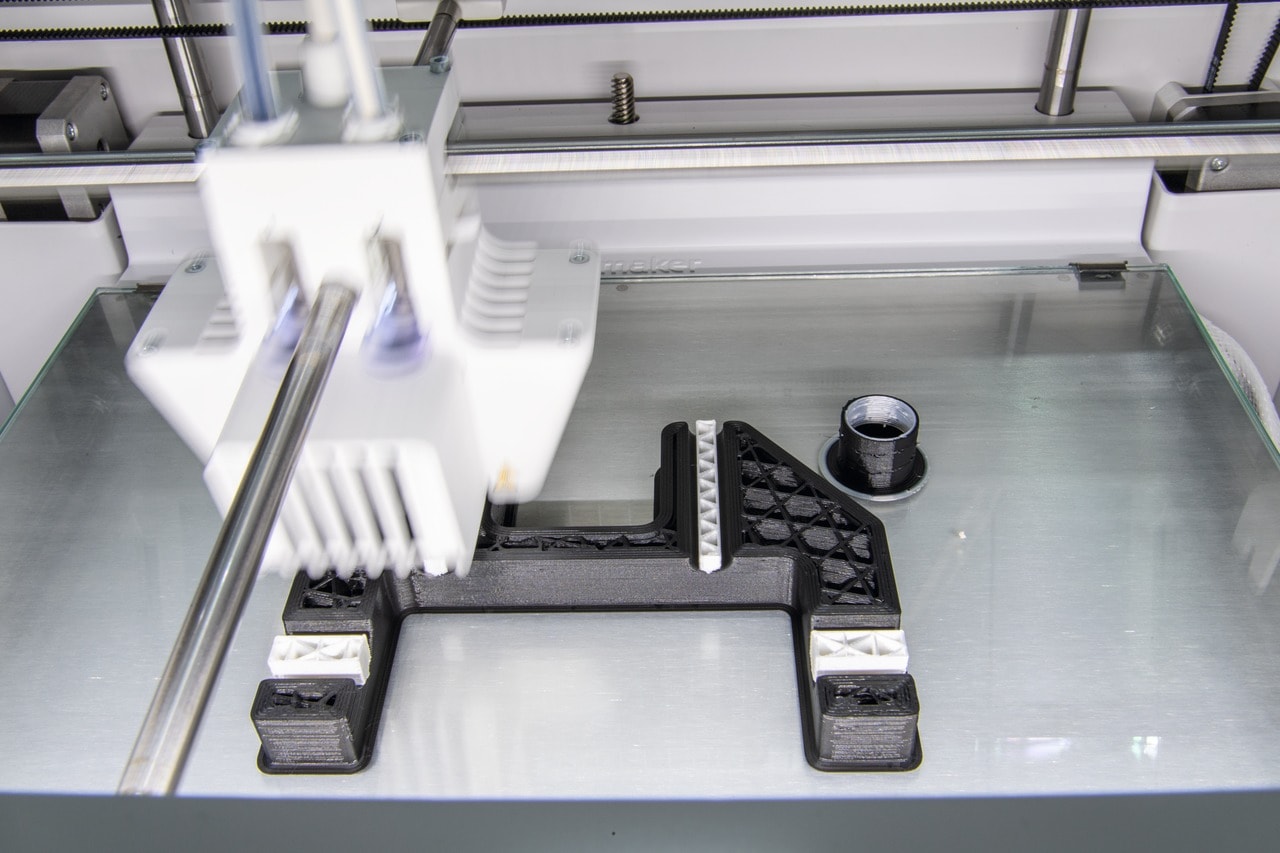

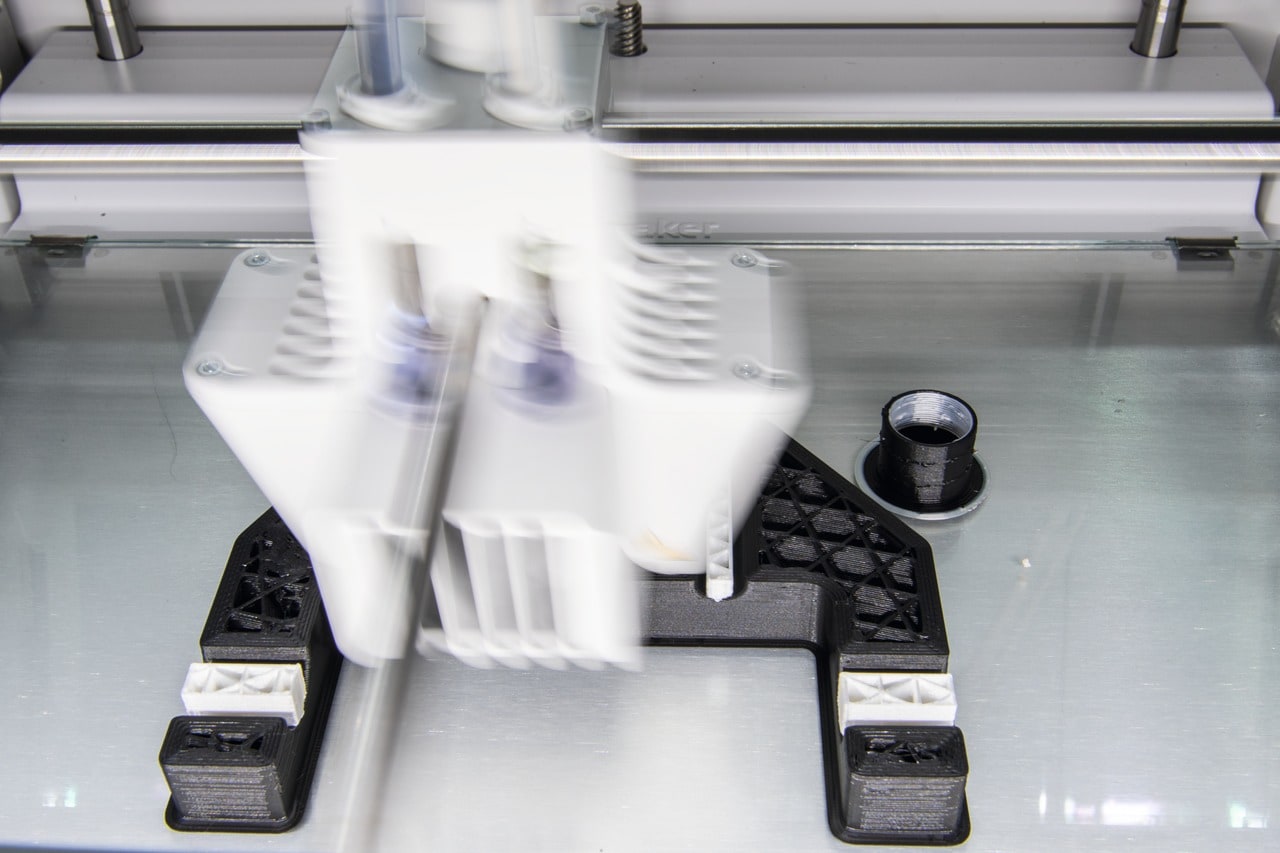

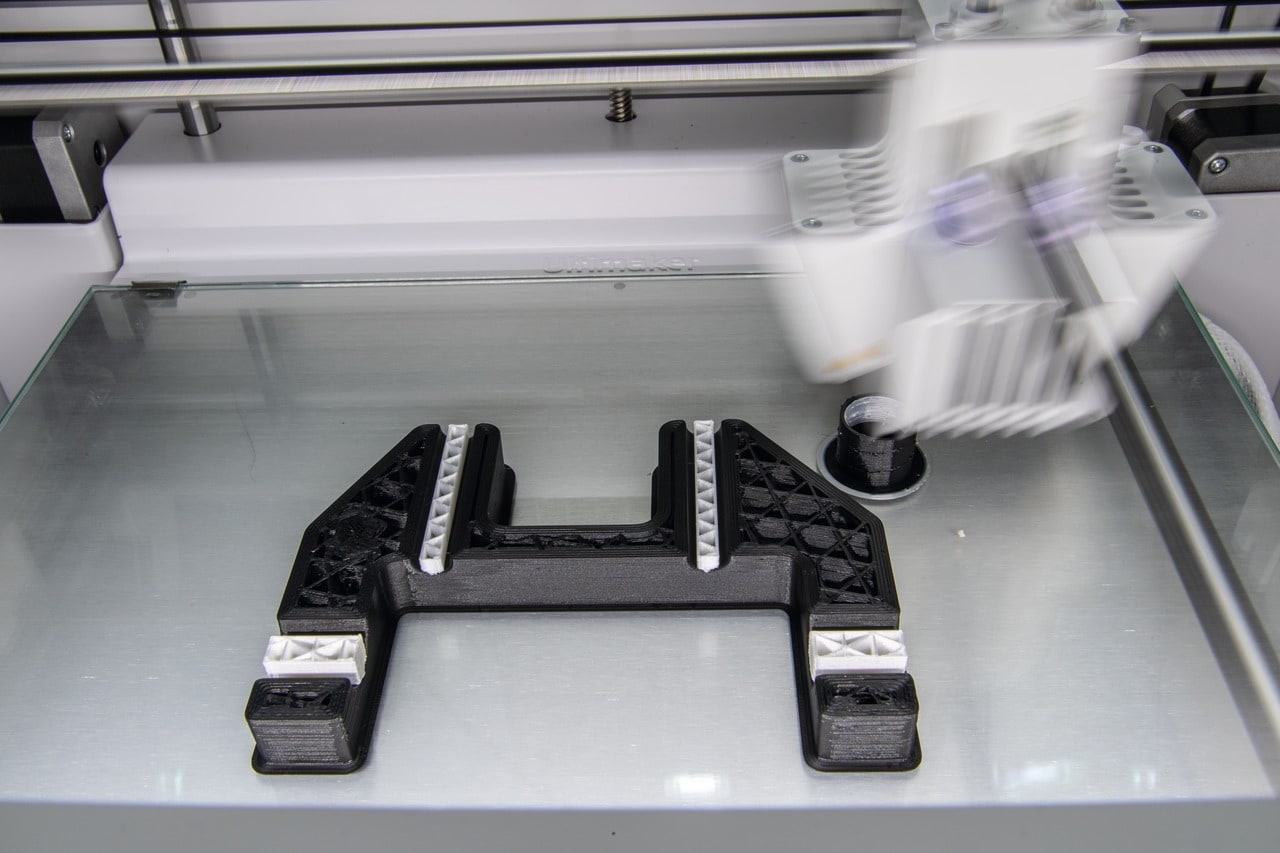

The solution is based on 3D printing technology, for which Krones offers its clients an all-inclusive package, comprising consultancy on the client-specific possibilities, the data needed for printing the spare in question, plus the matching 3D printer and the requisite expendables. Even though Krones has only been working on the development of Rapid Parts on Demand since mid-2020, print templates are already available for many different parts after just six months – and more are added on a continuous basis.

When a beverage producer opts for this solution, Krones first checks all the existing machines and recommends suitable print files for spares that are already available. On request, we also check whether there are other client-specific parts that are suitable for 3D printing. All print templates are then made available in the Krones.shop where the printing order can be started at the touch of a button, and its progress monitored. The entire printing process is thus completely transparent for the client, whose customised data are securely stored in the Krones Cloud.