Admittedly, not looking right or not fitting are out of the question, since the specifications have been discussed down to the tiniest detail when clarifying the order in the first place and the machine is configured exactly to the customer's requirements. Even so, many naturally want to assure themselves before delivery that the machine will be and do exactly what was previously agreed. And that's precisely why there are Factory Acceptance Tests, for which our customers come to the Krones plant and inspect "their" machine closely before the colossus – which may weigh several tons – embarks on its journey.

"Get something up and running quickly and easily"

But then came the bolt from the blue in early 2020, when global travel bans made visits to plants almost impossible and our internal protective measures against coronavirus prevented small groups from gathering in our buildings. Fortunately, an alternative was not long in coming: My colleagues Markus Müller, Oliver Riedhammer, Martin Heimerl and Michael Schuster eagerly worked out a concept within just a few weeks for performing an FAT for block lines without the need to be physically present on site. In the meantime, these live remote FATs based on this model are also carried out for fillers, blow-moulding machines, labellers, packers, cleaning machines or process technology systems.

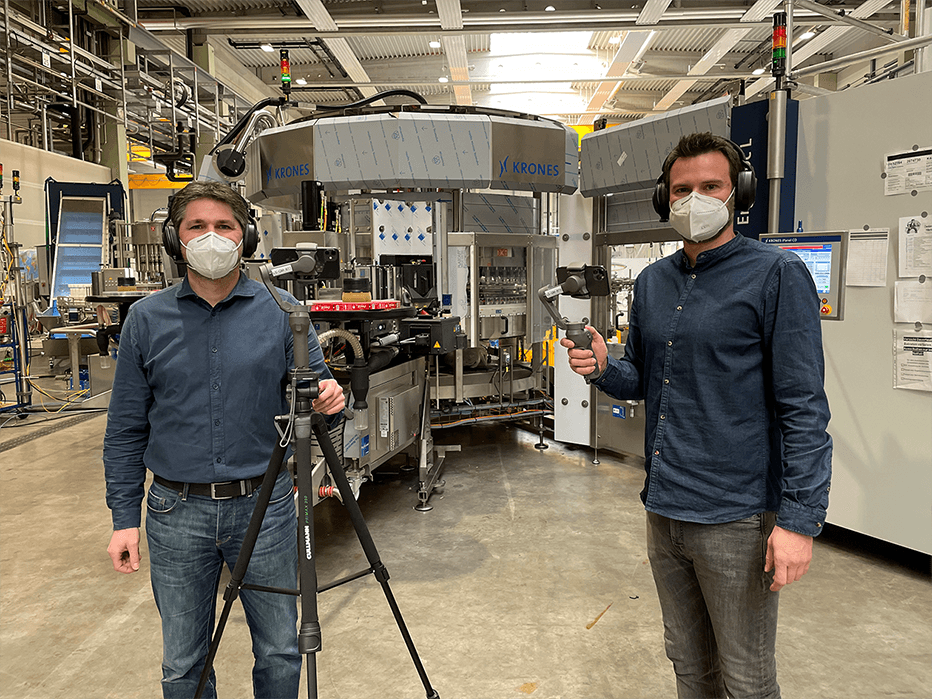

How this works is easy to explain: For recording, the colleagues on site use a mobile phone and a gimbal that stabilises the mobile phone. The client, in turn, is connected live to the hall via Microsoft Teams.

The FAT specialist from the engineering department is accompanied by the relevant project manager, who takes on the role of moderator and explains to the customer what is being shown. Both of them do so using commercially available headsets – with a noise-cancelling function, depending on the loudness of the machine. They are supported by colleagues who operate the machine and, for instance, ensure replenishment with preforms, bottles or labels.