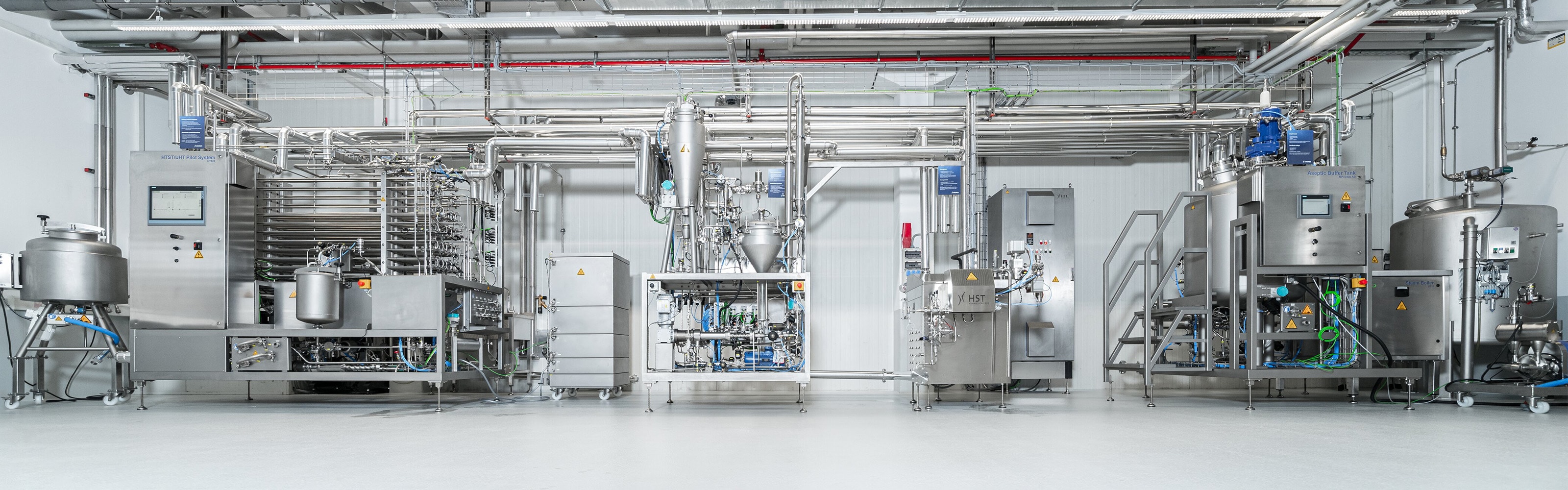

Imagine this: You work for a beverage company and have an idea for a new oat drink recipe. Before the drink can be produced in commercial quantities, you first have to test the idea on a small scale. And this is where many companies get stuck. It’s not at all cost effective to run tests like this on their own industrial-sized lines – the volumes involved would simply be too small and the interruptions to ongoing production too great. Not every company is in a position to have its own in-house development lab – certainly not start-ups that are only just dipping their toes into the market.