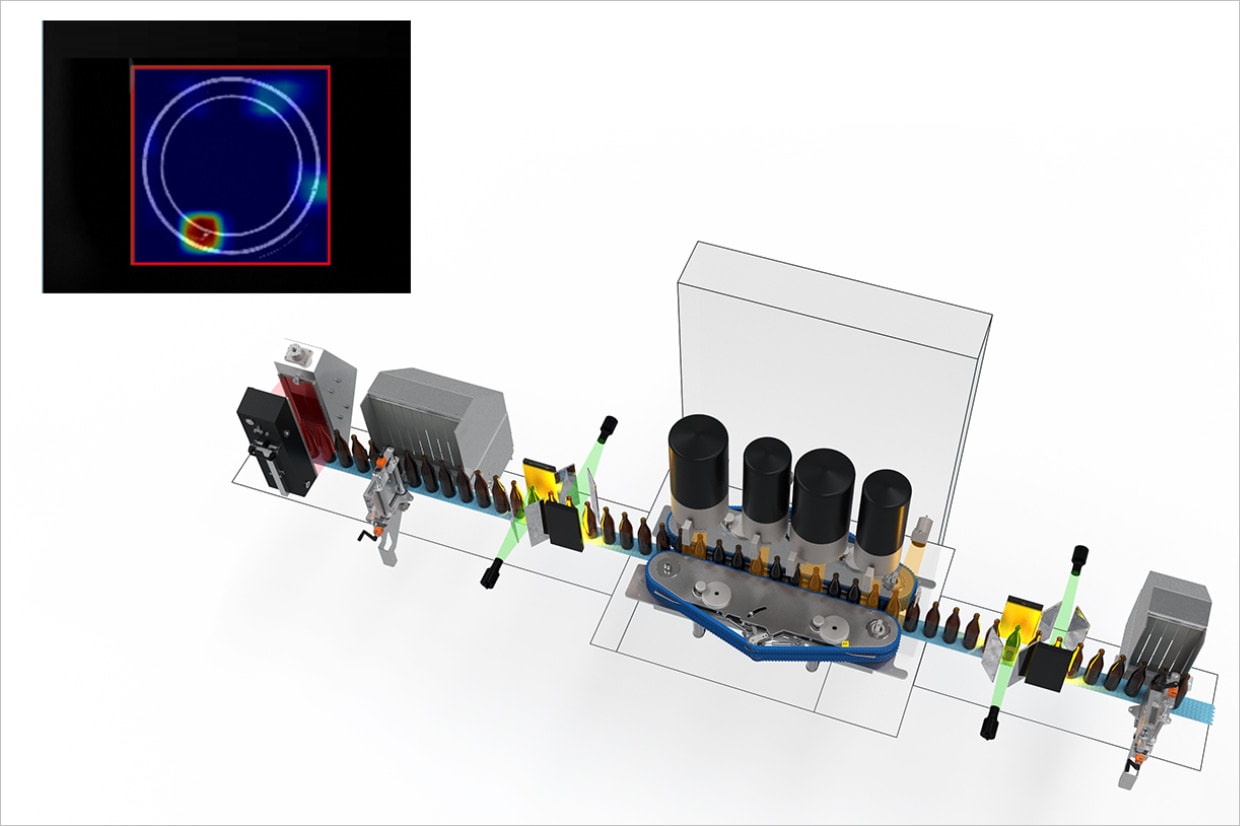

AI-based empty-bottle inspection for glass made its debut in 2020 when Krones launched the Linatronic AI, a pioneer in inspection technology that employs deep learning software to detect and classify anomalies. Instead of rigidly defined test parameters, it uses a neural network that was trained with a large set of example images.

During the inspection process, images are captured and then analysed through multiple consecutive filter layers. Each layer extracts a different characteristic of the image – ranging from simply identifying darker or lighter patches all the way to classifying complex structures. That allows the system to distinguish between a non-critical bead of water or harmless reflection – and a genuine defect like a crack or soiling.

The result: The number of erroneously rejected “good” bottles is in the Linatronic AI significantly smaller, making for a substantial reduction in material wastage. At the same time, the machine detects critical defects with a reliability rate of over 99.9 per cent. The system has for several years now proved its worth in practical operation. For example, breweries have reported that AI-based inspection software has minimised burst bottles at the filler, enabling them to enhance the stability of their lines’ overall performance.

As far as inspection equipment at Krones is concerned, artificial intelligence (AI) went from being just a vision to shopfloor reality quite some time ago: The launch of the Linatronic AI back in 2020 marked the arrival of deep learning technology in empty-bottle inspection. And now the smart inspector is getting some reinforcements: The new AI-based software includes solutions for checking cans and for final inspection downstream of the filler.

A glimpse into the inner workings of AI

Popping the hood reveals why this technology is ideally suited for inspection jobs: Deep learning models don’t learn from abstract rules but from practical examples. They are shown images of “good” and “bad” over and over again until they work out the relevant differences on their own.

For their users, that means the machine can be trained for product-specific jobs, like certain types of bottle, typical soiling or specific materials. If there is a change in containers or requirements, new data records can be fed into the network to modify it accordingly. That means it is possible to turn a technology, once developed, into a platform that can be adapted to suit a wide range of different inspection jobs.

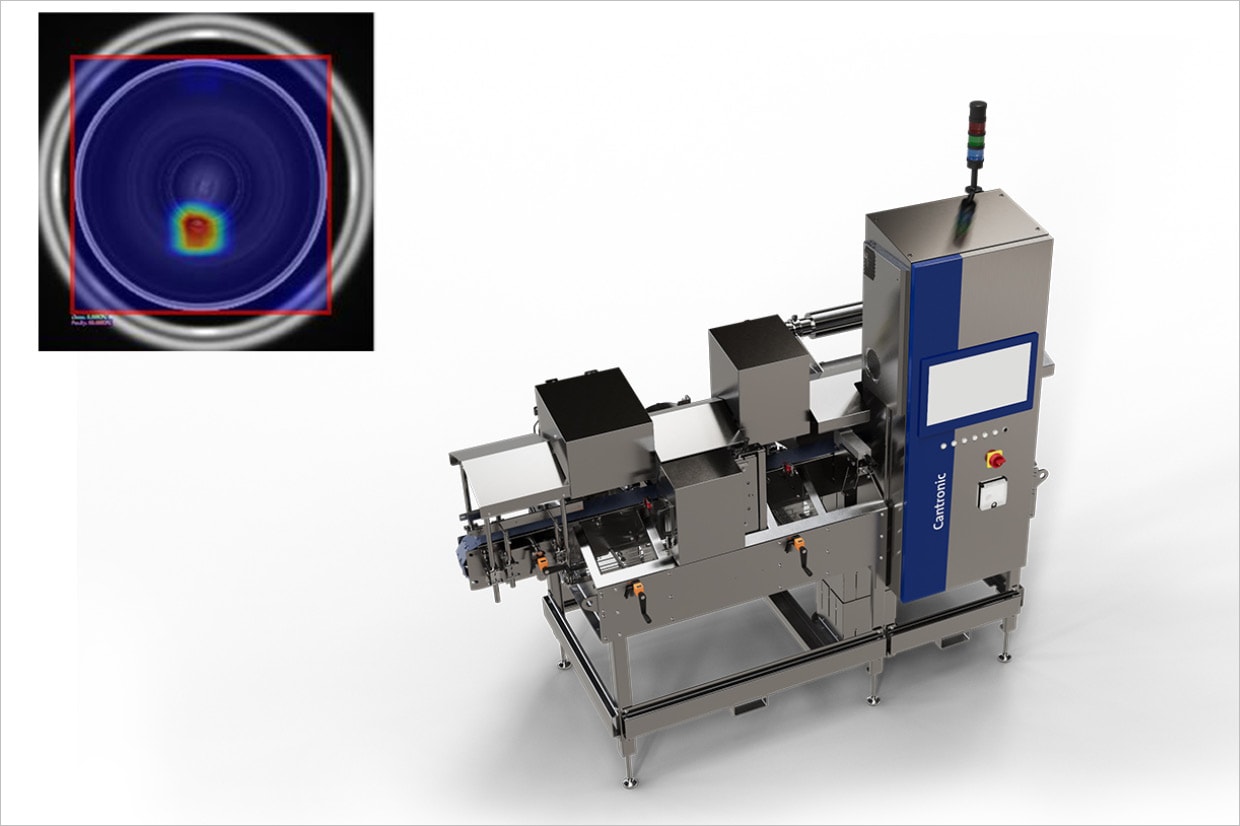

AI now inspects cans as well

And that is precisely what Krones has done in regard to can inspection. The Cantronic now has the option to be equipped with the same deep learning technology as the bottle inspectors, adapted to handle empty cans.

The challenge: Cans exhibit marked differences in terms of internal and external coatings and reflectance. Conventional systems quickly come up against their limits here because they need fixed threshold values. The AI-based Cantronic, by contrast, was trained with thousands of example images showing a diverse range of different cans and enabling the machine to reliably detect even the finest of contaminants – even if the visual appearance of the inside wall changes from one batch to the next.

Yet another advantage is this: Neural networks open up new detection options without the need for additional hardware. Typical foreign materials like a hair or thin plastic films, which have so far been difficult to spot, are reliably detected by the Cantronic AI. For its users, that means a reduced risk and enhanced product safety – with a short installation time and fast commissioning into the bargain.

The final checkpoint: Checkmat AI

While the Linatronic AI and the Cantronic AI handle empty containers, the Checkmat AI operates at a later point in the line, providing final inspection downstream of the filler. It employs the tried-and-tested deep learning technology of empty-bottle inspectors for checking the fill level and closure.

Inspection systems are faced with a difficult task, especially with carbonated or foaming products: Is the fill level really too low? Or is it merely covered by foam? Are the droplets at the closure a genuine defect or just beads of water from the rinser? The Checkmat AI has been trained to handle precisely such difficult jobs. The machine learns to deliberately ignore typical interference like product sloshing in the container or remaining beads of water and to concentrate on genuine anomalies.

In practical operation, that results in significantly fewer false rejects and a very high recognition rate. As a perfect complement, the Checkmat AI monitors the cap inclination angle, especially for non-returnable PET containers, thus making sure that every cap has been correctly placed – an important criterion for product safety and leakproof integrity.

Integrated into modern line concepts

The Checkmat AI plays off its strength not only as a stand-alone unit but also as a constituent part of holistically engineered concepts like Ingeniq. Designed for filling still water into PET containers, Ingeniq combines high-end equipment with digital services and a comprehensive service package.

AI-based inspection software upgrades efficiency in several respects here: automatic make-ready routines at camera and rejection systems support fast change-overs, deep learning algorithms ensure best possible monitoring of the product, and electric closure blow-off units reduce energy consumption as compared to compressed-air solutions. All of that makes an “intelligent inspector” an important factor in boosting a line’s overall performance.

From a single machine to a learning-enabled inspection universe

A clear-cut path is evident from its first use in the empty-bottle inspector all the way to AI-based inspection of cans and final inspection: Krones is gradually transferring the expertise it has gained with deep learning software to additional inspectors and fields of application. Users thus benefit from less wastage, increased process safety and reliability and a higher degree of flexibility for handling different containers and products.

And the potential is a long way from being exhausted. Because every new project supplies additional image data, enabling the neural networks to learn even more. As a result, inspection technology is gradually evolving into a learning system environment where artificial intelligence and practical experience go hand in hand and boost quality levels.