It’s 8am, rush hour in Zagreb, Croatia’s capital city. Traffic on the major roads is bumper-to-bumper. And right there in the thick of it, you’ll find trucks loaded with pallets from Zagrebacka Pivovara, whose brewery and bottling plant are right in the city center, surrounded by residential buildings, restaurants and small shops. From a logistical standpoint, it’s not exactly the best place for Croatia’s biggest brewery, “but we’ve been here ever since the brewery was established back in 1892 – and we’re staying loyal to this location,” says Brewery Operations Director Aleksandar Simovic. Zagrebacka Pivovara became part of the Molson Coors Beverage Company in 2012 and has been investing steadily in growth ever since. For example, on the filling side of things, the brewery put its first-ever canning line into operation in 2022. And this year, they replaced various machines on an existing returnable-glass line.

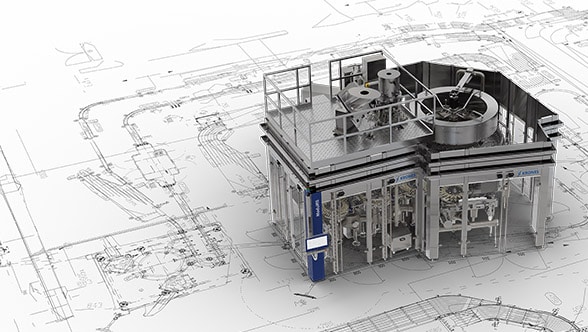

Zagrebacka Pivovara (which translates to Zagreb Brewery) is the biggest brewery in Croatia. To maintain the brewery’s leading position in the market, its management team stays abreast of trends – not only for producing new beverage brands but also when it comes to using innovative technologies. And now, Zagrebacka is also signposting the way in the field of filling and labelling – on a global scale: Since March, they’ve been running the very first Dynafill Bloc FL from Krones.

But with every new installation, the brewery faces the same daunting challenge: Because many of its buildings are decades old, space constraints and historic preservation rules make it impossible to expand any of the areas. And so, for example, the bottling hall is located in a three-story building – where every square meter is cleverly utilized: Four lines run in parallel, 24 hours a day on five to six days of the week, depending on the season. And all of those lines were supplied by Krones.

When, in 2023, the brewery’s leadership team began to consider upgrading the glass filling line, they turned to Krones. The plans focused on Line 2, which had been designed to fill 0.5-liter returnable glass bottles exclusively. Originally installed more than 30 years ago, the line has undergone some improvements recently: A few years ago, Krones replaced the unpacker, the empty-bottle inspector and several conveyors. Now, it was time to replace the main machines. However, steady high demand for Zagrebacka’s products meant that the machine swap had to be accomplished without stopping production.

And as if that weren’t challenging enough: Instead of “simply” replacing the machines, the company decided to go with an entirely new concept for filling and labelling. “When it comes to filling technology, there are not a lot of ground-breaking innovations. It has all been more or less very similar for years now. But what Krones offered was completely different – and of course, it sparked our interest,” says Aleksandar Simovic.

What Krones offered was completely different – and of course, it sparked our interest.

Aleksandar SimovicDirector of the Zagrebacka Pivovara brewery

Aleksandar SimovicDirector of the Zagrebacka Pivovara brewery

“It was revolutionary”

What he’s referring to is Dynafill – the only system of its kind worldwide, combining filling and capping into a single unit. “When we saw the Dynafill for the first time, the whole team was surprised. It fills a bottle one second and caps it in the next. It was revolutionary. There’s no other way to say it,” is how he neatly sums up the process. And although the Dynafill alone would have done quite a lot to help solve the space problem at Zagrebacka, Krones took it a step further: “They suggested that we directly block the Dynafill with the labeler – to reduce the footprint of both machines even more,” continues Aleksandar Simovic. “That was a big selling point for us since space really is a luxury item for us.”

When we saw the Dynafill for the first time, the whole team was surprised. It fills a bottle one second and caps it in the next. It was revolutionary. There’s no other way to say it.

Aleksandar SimovicDirector of the Zagrebacka Pivovara brewery

Aleksandar SimovicDirector of the Zagrebacka Pivovara brewery

But there was one hitch, as the brewery operations director recalls: “Normally it’s like this: Everyone thinks ground-breaking innovations are great, but no brewery wants to be the first to try them,” he laughs. Not so in Zagreb! Here, they decided to go for it and team up with Krones on the Dynafill Bloc Prototype project. “Would we have done a project like this with somebody else? Probably not. But we knew from experience that we can count on Krones even in challenging times,” says Aleksandar Simovic, recalling the commissioning of the canning line amid the covid-19 pandemic, when market demand had surged. “We – Krones and the team here – made it work!”

That experience emboldened Zagrebacka to take on this new project. “Of course, it wasn’t all smooth sailing right from the start – there will always be bumps early on. But this is the first block of its kind in the world,” says Aleksandar Simovic. As for the brewery’s ability to continue producing its flagship brand Ožujsko at the same level of quality and in the needed volume despite the prototype project – in peak season no less – Simovic credits that first and foremost to the excellent teamwork on site. “Everyone is really going all-out to make sure we manage the commissioning alright. It’s also great how our team was right here, looking and learning and working alongside, really getting to know the equipment first-hand,” he says.

Twofold benefits when it comes to safety

The Dynafill Bloc FL not only fits perfectly into the space available. It also provides significant advantages in terms of flexibility and performance. For example, it will in future handle not only the brewery’s own brands Ožujsko and Hidra but also other beers from the Molson Coors Beverage Company, which Zagrebacka produces for Croatia and neighboring Bosnia-Herzegovina and Serbia. The line is dimensioned to handle 55,000 returnable glass bottles per hour.

Besides the integrated concept itself, Simovic was especially impressed with the product quality that the Dynafill makes possible. “Of course, it’s a revolutionary concept technologically speaking. But what’s much more important are the advantages it offers for product quality. The fact that it fills and then immediately caps the bottles, without any additional air contact, means there’s less oxygen pickup in the beer. That makes for a more stable product, less potential quality issues and a longer shelf life,” he says. For Simovic, it boils down to this: “Ultimately, we, the brewery, aren’t the only ones to benefit. Our customers do, too. And that’s what matters in the end.”

What’s every bit as important in his eyes is the safety of his operating personnel. And here, too, the block concept has taken things to a new level: At the infeed and at the transfer to the Ergomodul labeler, MultiGuide Base multi-functional clamping starwheels were used, which eliminate the need for any manual interventions during changeovers. “Normally, our staff would need to swap out some 20 kilograms of handling parts. That work is now a thing of the past. The result is not only faster changeovers but also improved ergonomics and safety for our operating personnel,” says Aleksandar Simovic.

“A real game changer”

Although his responsibilities as brewery operations director prevented him from being present for parts of the commissioning process for the new machines, he was always well informed from day one. “With the block, we also have access to a digital solution, which allows us to monitor every aspect of the line’s performance. So, we always know how things are going. This is our first experience using a digital solution from Krones – but I wouldn’t want to be without it now,” he tells us.

The line is a real gamechanger!

Aleksandar SimovicDirector of the Zagrebacka Pivovara brewery

Aleksandar SimovicDirector of the Zagrebacka Pivovara brewery

If you ask Aleksandar Simovic what he thinks of the Dynafill Bloc so far, he’ll put it succinctly: “This line is a real game changer!” And he’s glad to have undertaken this project with Krones. “We’re the number one brewery in Croatia, and in order to maintain this position on the market, we have to invest in our company, in our markets and in the right technologies. With Krones, we’ve got the right partner for that.”

Updating the returnable-glass filling line in stages

-

1994: Installation of a returnable-glass line from Krones

-

2021: Part 1 of the update: Contipac unpacker, Linatronic empty-bottle inspector, two Robogrip units for loading and unloading pallets

-

2025: Part 2 of the update: Dynafill Bloc FL (FL: filling, labeling), VarioFlash B flash pasteurization system, Linajet crate washer and Contipac packer plus all container and pack conveyors from the empty-bottle inspector onward

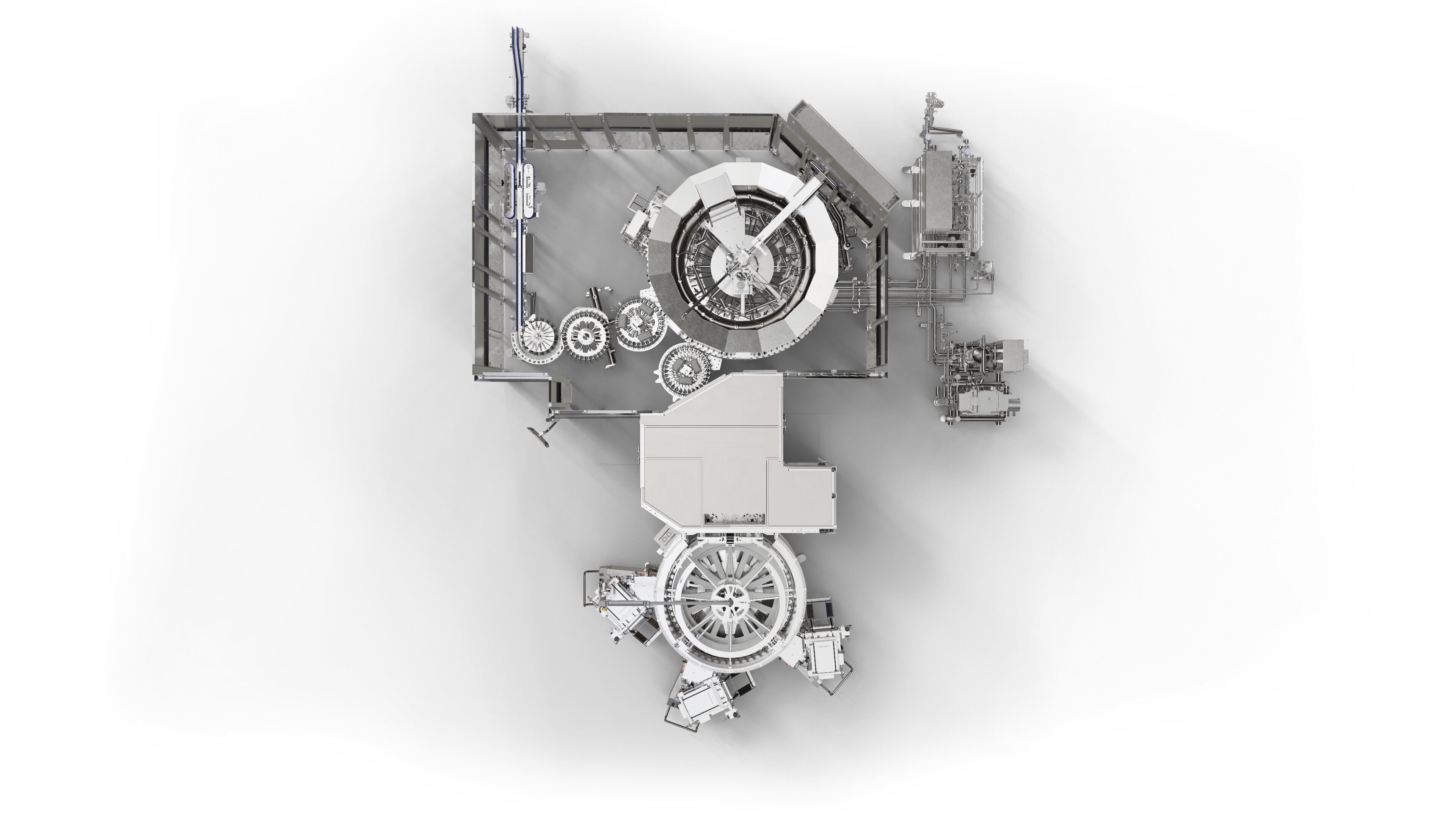

Dynafill Bloc FL at Zagrebacka – a bird’s eye view

Filler Dynafill with multifunctional MultiGuide Base clamp stars

Dry-compressing vacuum pump, valve node from Evoguard

- with three cold-glue labeling stations (neck, front and back labels) and a unit for applying tamper-evident seals

- Blower at the infeed to the bottle dryer

Checkmat FEM-X full-bottle inspector for checking fill level and label placement

This article provides a deep-dive into the Dynafill Bloc FL.