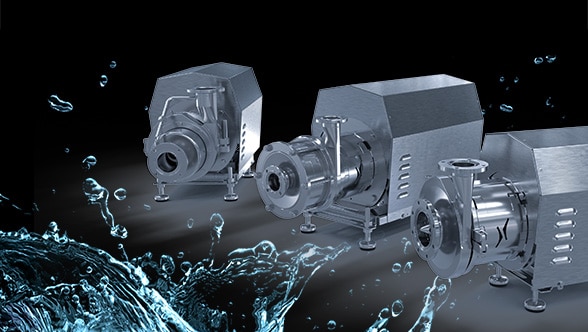

In late 2010, Krones premiered its own series of valves that were manufactured in-house. Then, in 2014, the company spun off its valve technology operations into Evoguard GmbH. The new company’s portfolio has grown steadily ever since, to include not only disk, seat, and double-seat valves but also aseptic seat and double-seat valves as well as pumps. And now, Evoguard has reached another historic milestone: The 500,000th valve has been sold – to the Portuguese Perfinox Group.

Sales Director Ivo Oliveira and Sandrina Mortagua, Sales Manager for Cambra-Sistem, Perfinox’s subsidiary for after-sales service, shared with us what they especially appreciate about the Krones subsidiary Evoguard.

Mr. Oliveira, Ms. Mortagua, what type of valve is this milestone valve? And do you know where it will be used?

Ivo Oliveira: It’s a classic disk valve. To be honest, we didn’t track exactly where it will be serving. But since our main activities are in food processing, we can say with some certainty that its application will also be in that field.