Ajyal is a food producer specializing in the trading and importing of edible oils and is headquartered in Surman, Libya. It is part of the Ajyal Holding Company, a group of 16 companies that are active in various sectors. Ajyal is a fast-growing privately held company that seeks to play a leading role in the food industry, particularly in the edible oil sector. Ajyal is trading refined corn oil under the Bruna brand to both Libyan and international specifications. The company currently serves the highly competitive local Libyan market. Ajyal’s customers are end consumers who the company reaches through representatives and merchants. One of the company’s goals for the future is to export its products to the broader African market.

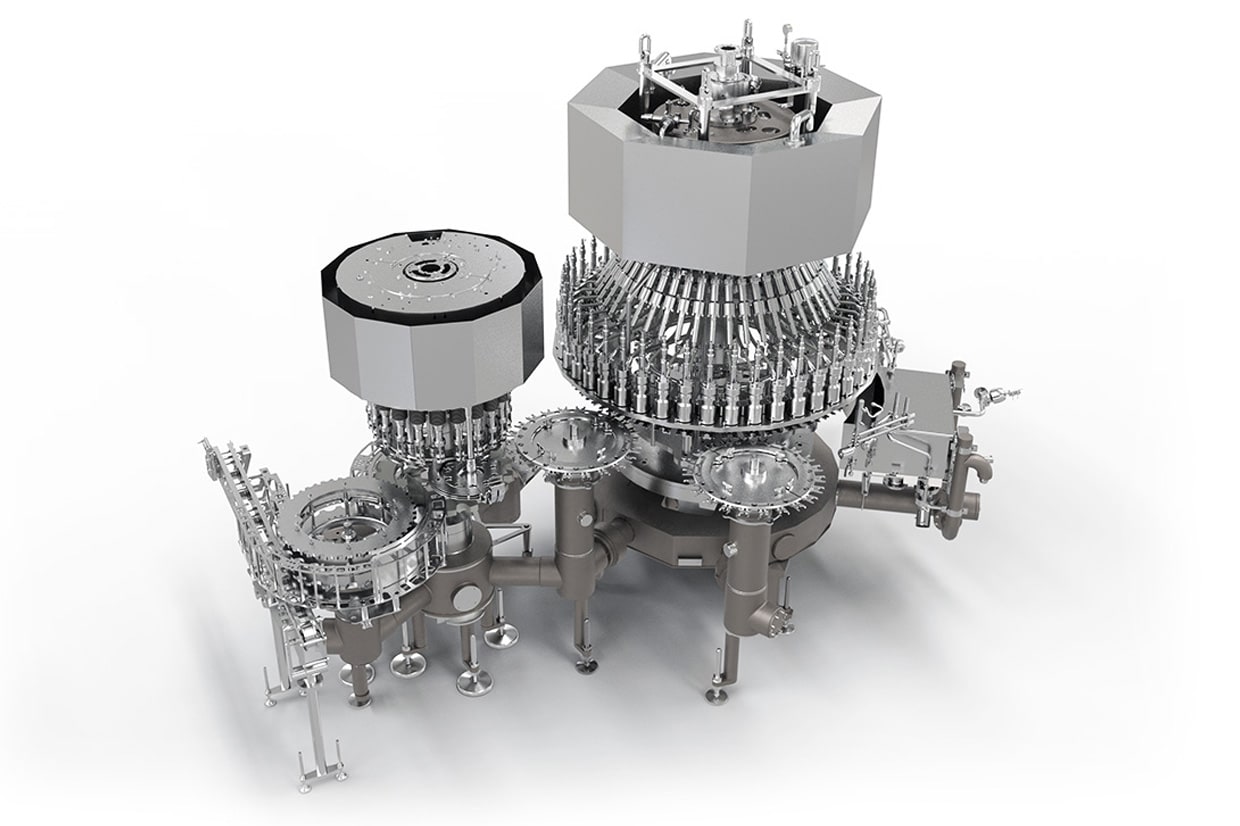

Based on their good market share and on detailed market research, Ajyal For Food Industries has decided to start with the production of edible oil themselves. To this end, the company has built a brand-new factory from scratch and installed a PET filling line rated at 24,000 bottles per hour, which was delivered entirely by Krones.

| Project: | Filling line for edible oil |

| Customer: | Ajyal For Food Industries |

| Location: | Surman, Libya |

| Commissioning: | February 2022 |

| Scope: |

The filling line for edible oil includes:

|

Special features:

The Modulfill NWJ filler was specially designed to handle viscous products like edible oils. It uses load cells to determine precise fill levels while a special filling valve prevents oil from dripping.

The filler handles just one size bottle: one liter. The bottles are capped with a flip top and dressed in a wraparound label. The filled bottles are distributed in 12-pack wrap-around cases.

“The most important advantages of the machines and the technology from Krones are their performance, dependability, and reliable output,” says co-owner Muadh Ahmed M. Albishti. “We chose Krones because it’s a leading manufacturer of food and beverage machinery. Krones helped us coordinate all of the materials for production and establish an efficient system for storing the individual components throughout our processes as well as the final product.” A third-party provider specializing in the installation of state-of-the-art production lines performed the installation under the supervision of Krones engineers.

The most important advantages of the machines and the technology from Krones are their performance, dependability, and reliable output. Muadh Ahmed M. AlbishtiCo-owner of Ajyal

At present, the supply of raw materials is limited by supply bottlenecks. “Nevertheless, our goal is to further increase our production capacity with yet another Krones line in the not-too-distant future,” says a hopeful Muadh Ahmed M. Albishti, who is satisfied with the current line efficiency of over 90 percent.