3. The commissioning

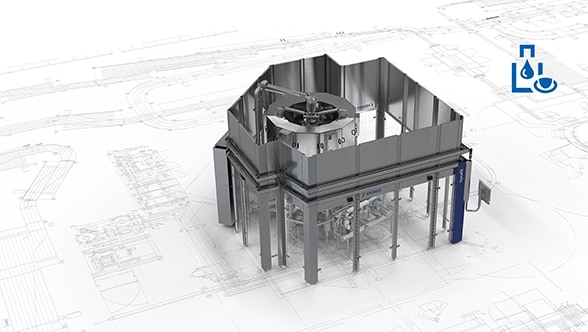

“Balter Brewing Company is an Australian craft brewery that has recently experienced tremendous growth. In order to meet the demand for its beer, Balter ordered a 50-hectoliter brewhouse from Krones for up to ten brews per day as well as a complete package of cellar equipment and a CIP system, which will also clean the Craftmate that has been in operation since 2018. Installation was handled by a local company. In April, the brewery was ready for commissioning. Under normal circumstances, we would always send a team from Europe to do the commissioning. But that wasn’t possible due to current entry restrictions.

First, we tried to get an exception for one of our European team members to be allowed to travel to Australia but were unsuccessful. We all knew this: if Balter was going to meet its production needs for this year, we had to act quickly. And so, together we decided to manage the commissioning remotely from Freising, Germany. Of course, we still needed help on site. And this is where the strength of the worldwide Krones family really came to shine. We were able to enlist the help of an Australian Krones service technician – an electrician whose specialty actually lies in bottling and packaging machinery. After completing a crash course on the Botec F1 control system, he was able to serve as an extended arm for his teammates in Freising. Balter also provided two experienced people: their own brewmaster and another brewmaster from within Australia’s CUB (Carlton & United Breweries) group, of which Balter is a member. The latter had already gained some good experience with Krones technology at the end of 2018, when a Steinecker CombiCube was commissioned in Adelaide. Together, the three formed the core team on site. They were guided online by two colleagues in Freising, who had initially intended to travel to Australia for the commissioning. One was a technology specialist, the other a software engineer.

And this motley crew did a fantastic job! They all took on the challenge readily – with no ifs, ands, or buts – and carried off the commissioning despite the unique circumstances. These extraordinary times call for extraordinary measures. Due to the 8-hour time difference, the team in Freising began their day in the middle of the night. But thanks to the videoconferencing function on Microsoft Teams, a VPN connection, and a lot of coffee, the remote commissioning went outstandingly well. The collaboration was so successful that the remote commissioning was completed ahead of schedule. The original target date was August, but it took less than four weeks from kickoff to the first brew! This accomplishment was possible thanks to the incredible flexibility and willingness of everyone involved to undertake this adventure. It was an excellent team effort on the part of Balter and Krones alike. As a result, we were able to overcome all obstacles and get the additional brewing capacity Balter so urgently needed up and running.”