Artificial intelligence is everywhere these days – in images, in text, in processes and in products. We often don’t even notice it’s there. Take this example: An AI-generated video that came out in 2025 and appeared to show Will Smith eating spaghetti created quite a stir online because it looked so realistic that many people thought it was real. It is proof positive of how far the technology has come in a very short time. In the beverage and liquid food industry, too, AI is opening up new possibilities that would have been unthinkable just a few years ago.

Artificial intelligence (AI) is changing the way we live, work and make decisions. At Krones, we’re using it where it makes a real difference: for increased efficiency, sustainable solutions and smart processes.

Solving customers’ challenges with AI

Beverage companies face myriad challenges these days: a lack of skilled workers, a desire for more sustainability, increasing complexity in portfolios and production, and pressure to operate more and more efficiently. For Krones, this much is clear: Overcoming these challenges will require innovative solutions. “We didn’t start using artificial intelligence because everybody else is using it but rather because we wanted to offer solutions to the biggest challenges our customers face,” explains Philipp Olenberg, Head of Artificial Intelligence at Krones.

For Krones, AI is not an end in itself but rather a means by which to collaborate with customers to find answers to the industry’s most pressing questions – such as how to make production processes more flexible, how to conserve resources and how to achieve greater transparency in the supply chain. In all of these efforts, the focus is on specific benefits: “Krones is in the same boat with its customers: Together, we want to develop solutions that truly help,” says Philipp Olenberg.

AI in use – four paths to smart production

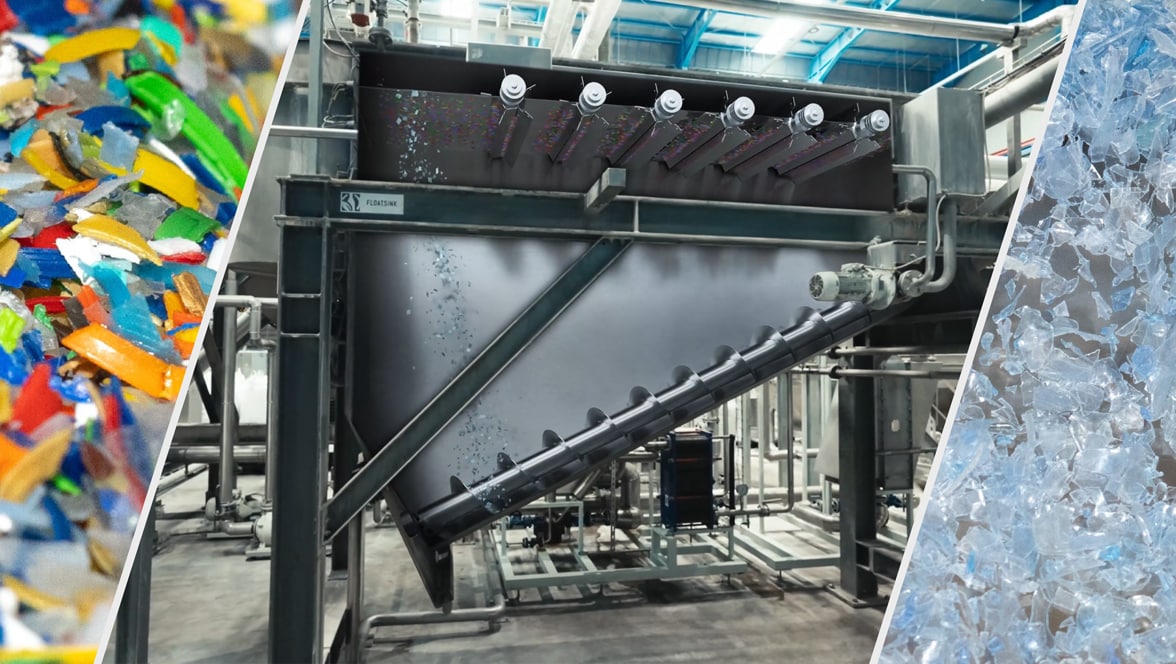

Although artificial intelligence alone can’t solve every problem, it certainly helps when it comes to designing smarter processes and supporting beverage companies in a purposeful way. That is why Krones uses AI where it creates real added value. “AI helps us, together with our customers, to master industry challenges and to set new standards in productivity and sustainability,” stresses Philipp Olenberg. An example of this is Ingeniq: The new line concept for filling still water into PET bottles at high speeds combines data-based intelligence with fully automated processes. It is the answer to key customer requirements such as low total cost of ownership and high efficiency, and it shows how AI technology can translate visions into real solutions.

Krones is not new to AI: For several years now, our AI team has been working on the purpose-driven transfer of intelligent technologies into the context of beverage production. Several solutions are already in use, while others are the focus of intensive development efforts.

Here, it’s all about intelligent analysis of sensor data from machines and lines. Systems like Contiloop AI and Dynafill AI monitor and control production processes fully automatically. They respond flexibly to changes such as temperature fluctuations or varying product parameters, ensuring consistently high quality and minimal waste. The system also reduces the burden on operating personnel because the AI is able to make adjustments autonomously and thus keep production running smoothly. Prize-winning solutions like Contiloop AI, which earned the AI Breakthrough Award 2023, and Dynafill AI, which won the AI Excellence Award 2024, show how AI can be used to reduce energy consumption, minimize waste and increase product quality.

Another area of application is condition monitoring: With Shopfloor Guidance, machine data are continuously analyzed to detect anomalies and wear at an early stage. For example, vibration serves as an indicator of the condition of components like rollers. The AI automatically determines the suitable threshold value and is able to reliably distinguish between actual levels of wear and false alarms, such as might occur after commissioning. The solution automatically groups and prioritizes all tasks, informs the responsible personnel and, in so doing, helps to resolve problems in the line efficiently and at an early stage. It also detects anomalies and reports them directly to the right person, thus preventing unscheduled downtimes and helping to keep production moving along.

Computer vision lends transparency to production. It combines modern camera systems with deep learning technologies to ensure that collected images are interpreted intelligently. With it, inspection technology, which is responsible for assuring the quality of containers and products, is able to detect even the tiniest anomalies, reduce the number of false rejects, and ensure a high level of inspection accuracy.

Line Observation is a new Krones solution that uses computer vision to monitor the entire production process. Integrated camera technology and AI-based analysis help to detect and correct issues at an early stage – even remotely. As a result, line productivity increases without the need for personnel to be present at the machine at all times.

Here, the AI supports production planning and control. AI Order Sequencing can be used to create optimal production sequences, minimize changeover and cleaning times and maximize capacity utilization. The solution takes into account individual criteria such as deadlines, maintenance intervals and special campaigns and adapts flexibly to current requirements, ultimately making planning more efficient and far less stressful.

The latest addition to Krones’ AI toolbox is language-based assistance systems and chatbots that make it easier for personnel to interact with digital solutions. They help quickly evaluate large volumes of data, generate reports, and support employees in analyzing production data. In this way, they make knowledge more accessible for faster, better decision-making. Development in the area of generative AI is advancing rapidly at Krones. Our goal is to make the analysis and operation of our machines and lines even more intuitive and efficient.

Looking ahead

The speed of development in artificial intelligence is tremendous. What was, just yesterday, still a vision for the future is now reality – and it’s already changing entire industries. For Krones, that means we can’t stop at the progress we’ve made so far. We must continue to actively drive development so that we can deliver the greatest possible benefit to our customers. And so, we will continue to upgrade existing AI applications and expand into new areas of application. For example, in the future, additional monitoring areas will be integrated into Shopfloor Guidance in order to obtain even more comprehensive information about the condition of machines in the production line. All in all, we are shifting from purely condition-based monitoring to predictive maintenance. That will enable early detection and targeted prevention of potential faults which, in turn, translates to greater system availability and planning security. Krones is working on AI solutions along the entire life cycle of the line, with an unwavering focus on making production smarter, more efficient and more sustainable.