When the Kliafa family set up their business in 1926, they were the first beverage bottlers in Greece to own a machine for filling soft drinks – back then at a speed of 120 bottles per hour. The company, which joined the Hellenic Dairies Group in 2020, still prefers to be one step ahead of the market today. Its portfolio includes soft drinks free of sugar and preservatives because Greek consumers, too, are setting an ever-greater store by healthy foods and beverages. According to the Future Consumer Index Greece 2021, three out of four Greeks intend to do more for their own health in the long run and are prepared to change their shopping habits in favour of higher-quality products and to pay more for them, too.

Almost 100 years ago, the Kliafa family started filling its soft drinks in the heart of Greece. An aseptic PET line from Krones now helps them combine traditional craftsmanship with innovation.

Colourful portfolio

Krones technology has now enabled the beverage producer to fill not only glass bottles with its colourful drinks but also PET bottles in an aseptic process which guarantees microbiological safety and renders preservatives superfluous. The portfolio includes soft drinks with orange, lemon or sour-cherry flavour, either still or carbonated, with or without sugar and preservative-free, as well as mineral water. The latest addition is called BiBi Cola, which is likewise available with or zero sugar. Ultra-delicious: The three flavours sour cherry, orange and lemon have won the Superior Taste Award label of the International Taste Institute.

In addition to health aspects, quality and taste are also top priorities: Since Kliafa’s plant is situated near the Pindos mountains renowned for their pure springs, the company can use premium-quality water for its products. What’s more, the soft drinks are made of 20 per cent not-from-concentrate fruit juice from Greek fruits.

Aseptics for sensitive beverages

In order to ensure secure filling of its new, healthier beverages, Kliafa has opted for a turnkey aseptic line from Krones. For Athanasios Kolovos, the company’s managing director, the decision was obvious: “Krones is a company you can rely on and offers us state-of-the-art technologies. Moreover, a crucial factor tipping the scales in their favour was their local service operation here in Greece.”

In 2021, Kliafa invested 18 million euros in the construction of new buildings and an aseptic PET line. The project was implemented at record-breaking speed: Construction work for the hall started in September 2020 and the first bottles were produced just seven months later, in April 2021. The line was then successfully acceptance-tested in June, which was fittingly celebrated with an official inauguration party. “The timeline was extremely crowded, with only three months between the line’s installation and commissioning,” to quote Athanasios Kolovos.

| Project: | Aseptic line for filling soft drinks |

| Customer: | Kliafa Family S.A. |

| Location: | Trikala, Greece |

| Commissioning: | June 2021 |

| Scope: |

PET line handling beverage containers ranging from 0.33 to 1.5 litres in size, rated at 23,000 bottles per hour, including:

|

P for performance

The Contipure AseptBloc DA-P is the heart of the line. It comprises a Contiform 3 Pro stretch blow-moulder with preform sterilisation system and an aseptic filler, thus ensuring aseptic processes throughout all phases of bottle production and filling while also achieving record-breaking line availability levels. Athanasios Kolovos is full of praise: “The CIP cleaning routine in the filler takes a mere one and a half hours, and the entire line has been designed for maximum operator-friendliness. All systems are fully automated and easy to use. While production is running, our operators can access all data in real time, making it substantially easier for them to manage all the processes involved.”

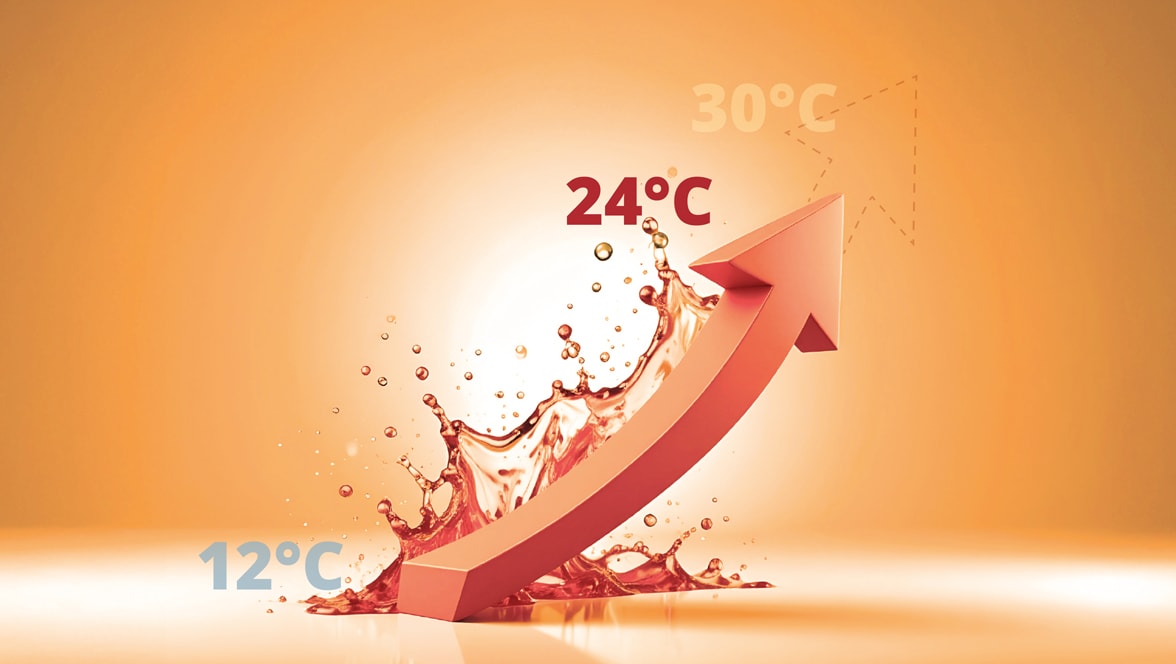

Product integrity is the paramount priority, of course. It is ensured firstly by the Contipure AseptBloc DA-P which sterilises all of the preforms’ surfaces – meaning inner and outer surfaces, plus neck area – simultaneously using gaseous hydrogen peroxide (H2O2). That is an especially gentle method which leaves almost no residues because in the subsequent stretch blow-moulding process the preforms’ surface is enlarged many times over and the last traces of the sterilisation medium are correspondingly diluted. What’s more, the system consumes no water at all during production, which denies microbiological organisms any habitat whatsoever. This particularly safe filling method is instrumental in providing a guaranteed shelf life of six months for Kliafa’s preservative-free beverages.

The Contipure AseptBloc DA-P at a glance

- Suitable for

- high-acid products

- round and square PET containers

- standard and lightweight containers

- Output: up to 70,000 containers per hour

- Extra short sterilisation phase of only 90 minutes

- Extra short intermediate-cleaning time of only 30 minutes

Implemented in record time and backed by reliable service support

In addition to the extremely crowded timeline, the special design of Kliafa’s bottles constituted yet another challenge for the project team. Both fruit-flavoured soft drinks and cola are filled into 0.33- and 1.5-litre bottles, with the cola bottles having a different shape. What’s special about Kliafa’s bottles is that they are dressed in neck labels applied in one piece round the bottle neck and over the entire closure. In order to ensure top labelling quality for this unusual outfit, the bottles’ neck finish design, the area covered by the label and the closure all had to be optimally aligned for a perfect match.

“We’re very satisfied with the mutually supportive relationship we have with Krones,” explains Athanasios Kolovos. He’s got praise not only for the company’s reliability and state-of-the-art technology but also and especially for the service support provided: “First things first: We really appreciate the short installation time. Cooperation both with the German and the Greek teams went like clockwork. We’ve also concluded a two-year service agreement for the filler and the stretch blow-moulder and can thus rely on the support specialists from Krones.”

We want Krones as a can-do partner for our future steps.

Athanasios KolovosManaging director at Kliafa

Athanasios KolovosManaging director at Kliafa