The market for bottled water in Saudi Arabia is expected to grow organically by almost nine percent annually through 2025, driven in part by a shift toward mass production of water in PET bottles. Although the market is highly competitive, it is also an open one with room for new developments.

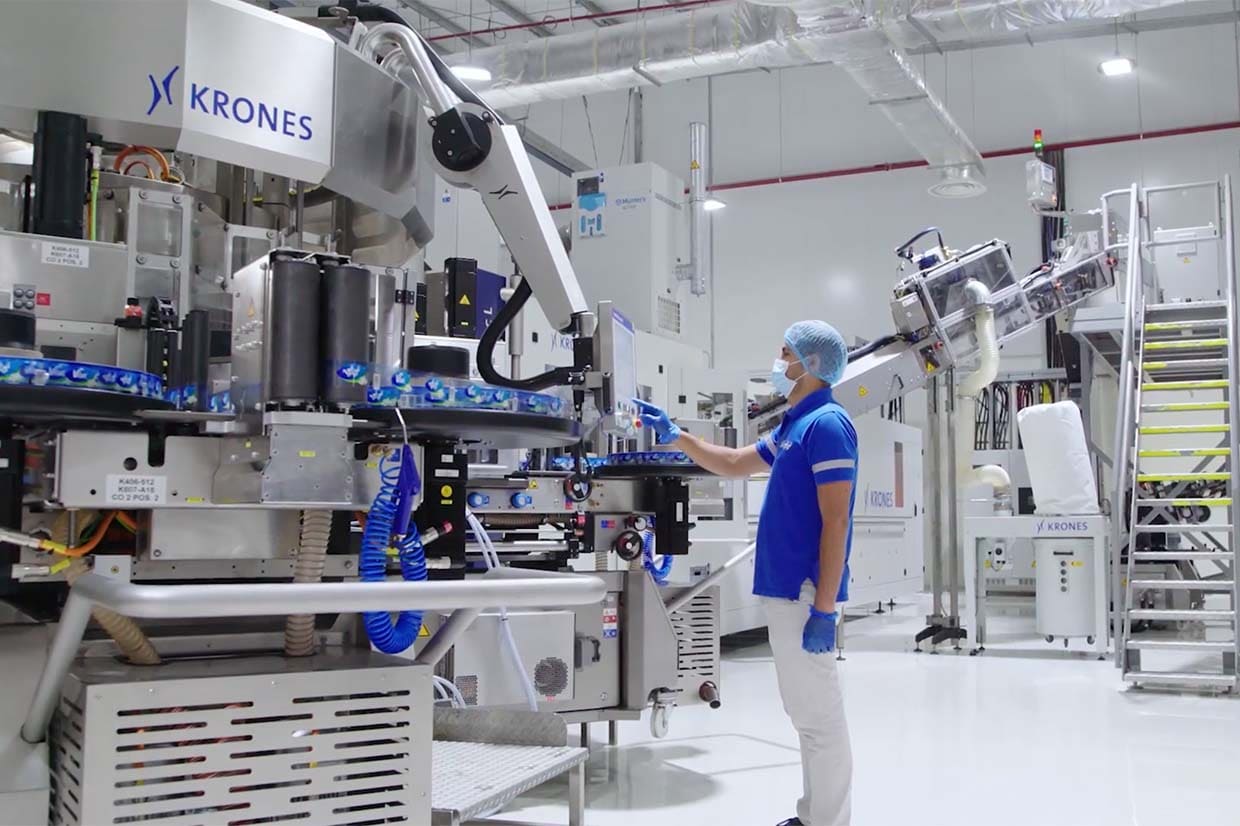

One recent entrant is Jasmine Water and Beverages Factory (JWBF), behind whose parent company is a highly regarded Saudi family who have previously focused their activities on real estate, agriculture, and general investment. The family now aims to redefine the packaged water business in the region, running an eco-friendly bottling plant: There, it takes less than one hour for the water to travel from the deep wells into bottles, so there’s no storage involved and no chlorine is used in product water processing.