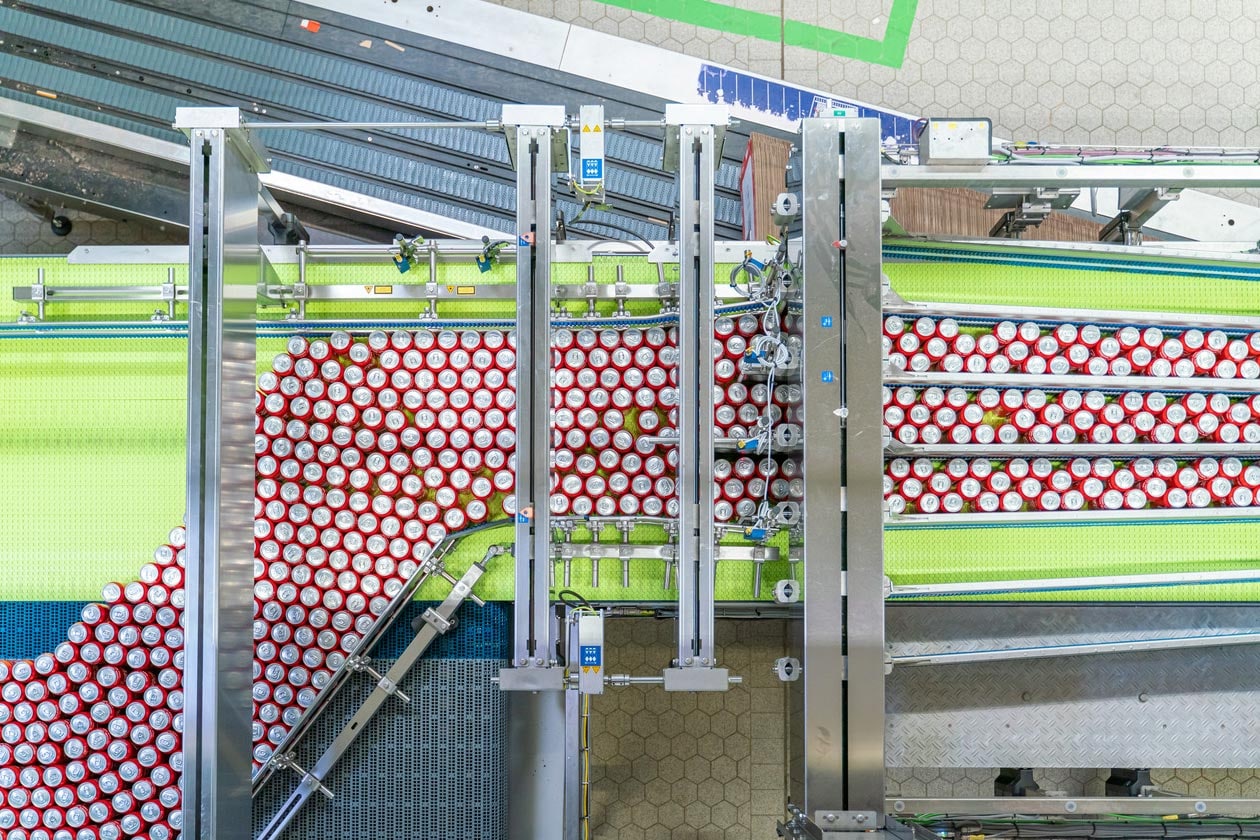

The beverage can is on the up again in Germany, boasting vigorous growth rates. According to a survey conducted by Global Data, in 2020 its market share increased by 11.8 per cent over the preceding year’s figure in the soft-drinks, beer and cider segments and came to nine per cent of all beverage packaging materials. (By way of comparison: In Europe, the can already accounts for 24 per cent of the total.) A gratifying development, especially when you look back at what it was like about 18 years ago. After Germany had introduced the mandatory deposit on non-returnable containers in 2003, the beverage can vanished almost completely from the supermarket shelves. Now, nearly two decades later, the can is back!