Block line system for every beverage filling: Compact, efficient, and customisable

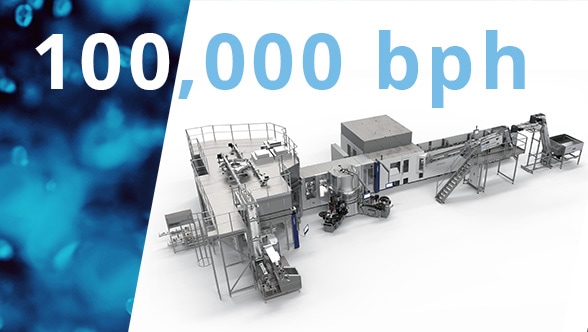

Whether soft drinks, dairy products, fruit juices or beer: there is an appropriate block solution for the filling of just about every beverage. Block solutions comprise multiple handling steps in one compact system. The result: less space needed, less to operate – but entirely harmonious processes and visible efficiency along the entire process chain.

As modular component systems, block solutions can be individually configured: from stretch blow moulding and labelling through to filling and capping, everything that needs done in the wet section of a beverage plant. And not only for standard applications, but also for special challenges such as preforms made of rPET or aseptic products.

By the way: just like PET containers, cans can also be handled in blocked systems – with the same benefits for efficiency.