In the Alpine foothills of Upper Bavaria lies Maxlrain Castle, a Renaissance castle framed against the backdrop of Wendelstein mountain. It is home to one of Germany’s most beautiful golf courses stretching over 140 hectares, a venue for large open-air concerts, a vintage car show and medieval tournaments. All that’s missing is a cosy brewery with an authentic beer garden to perfect the picture. But of course Maxlrain Castle, which is owned by Dr. Erich Prinz von Lobkowicz and lies about 60 kilometers south of Munich, has that too.

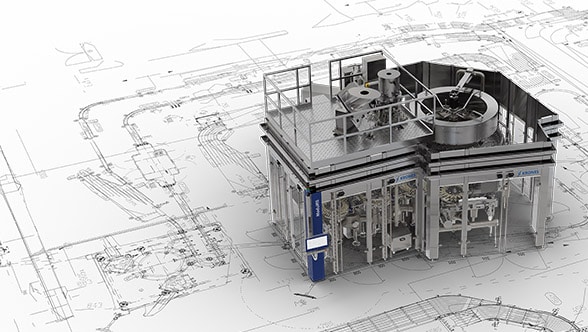

Maxlrain Brewery