“Just as the filler was loaded on the boat and ready to go, the waters began to rise,” recalls Friedrich Hein, Project Manager for Production and Digital Transformation at CCEP DE, about that day the previous year. One of the biggest fillers Krones had ever built – weighing 23.5 tons – was about to set sail from Regensburg to Lüneburg. Multiple construction projects on Germany’s Autobahn highways meant that heavy-freight transport by road was out of the question – so the decision was made to ship the filler by water.

The arrival date was set for a Saturday so as not to interfere with the plant’s production operations. But getting the timing right turned out to be an exercise in patience, because high waters threatened to prevent the ship’s passage. For days, it was unclear whether it would be able to dock on schedule. “It was a real nail-biter,” says Friedrich Hein. In the end, it all worked out and the ship reached Lüneburg’s snowy harbor as planned.

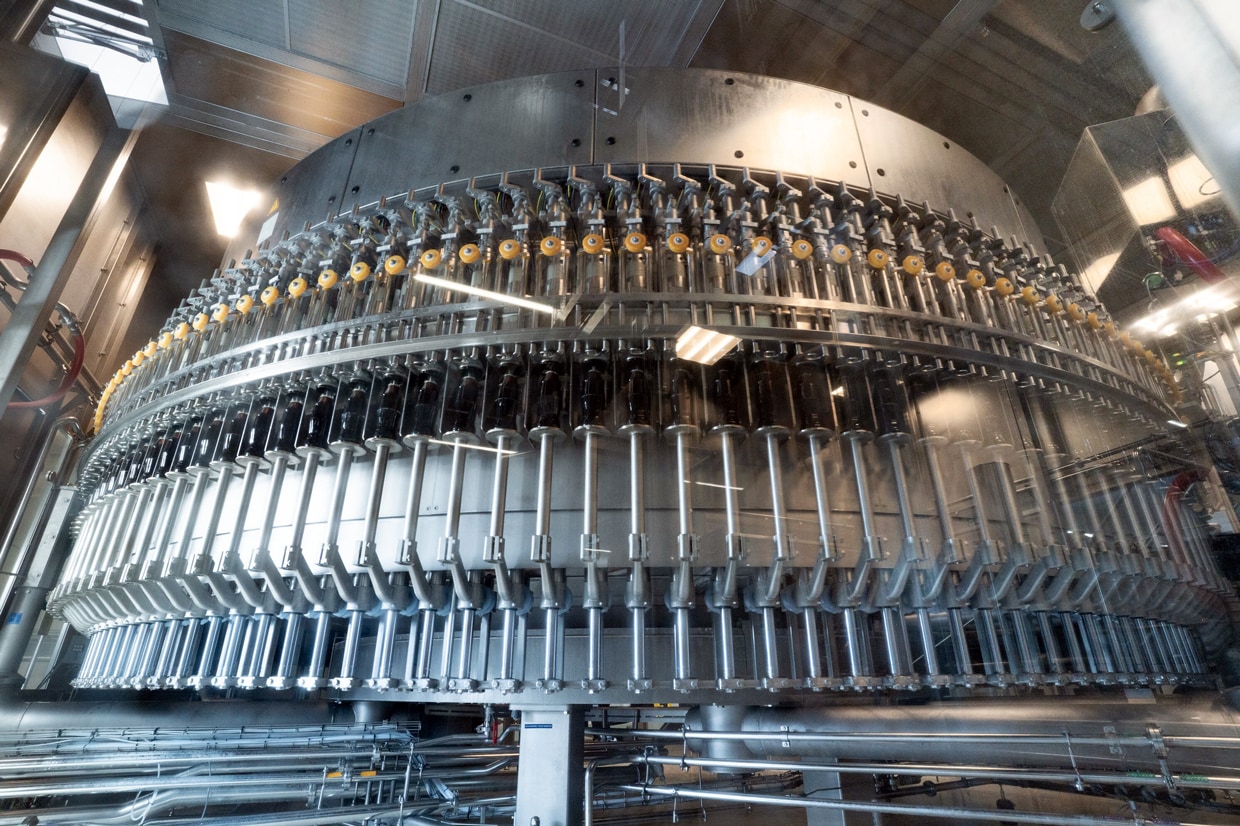

The Lüneburg facility is one of 13 production sites operated by CCEP DE – and with its new glass line, it’s an important catalyst for beverage filling in the north. The Modulfill HES filler is the heart of the line, which is the second of its kind here. The plant supplies Schleswig-Holstein, Hamburg and parts of Lower Saxony and Mecklenburg-Western Pomerania, with a focus on short transport distances, low emissions and a consistently regional orientation.

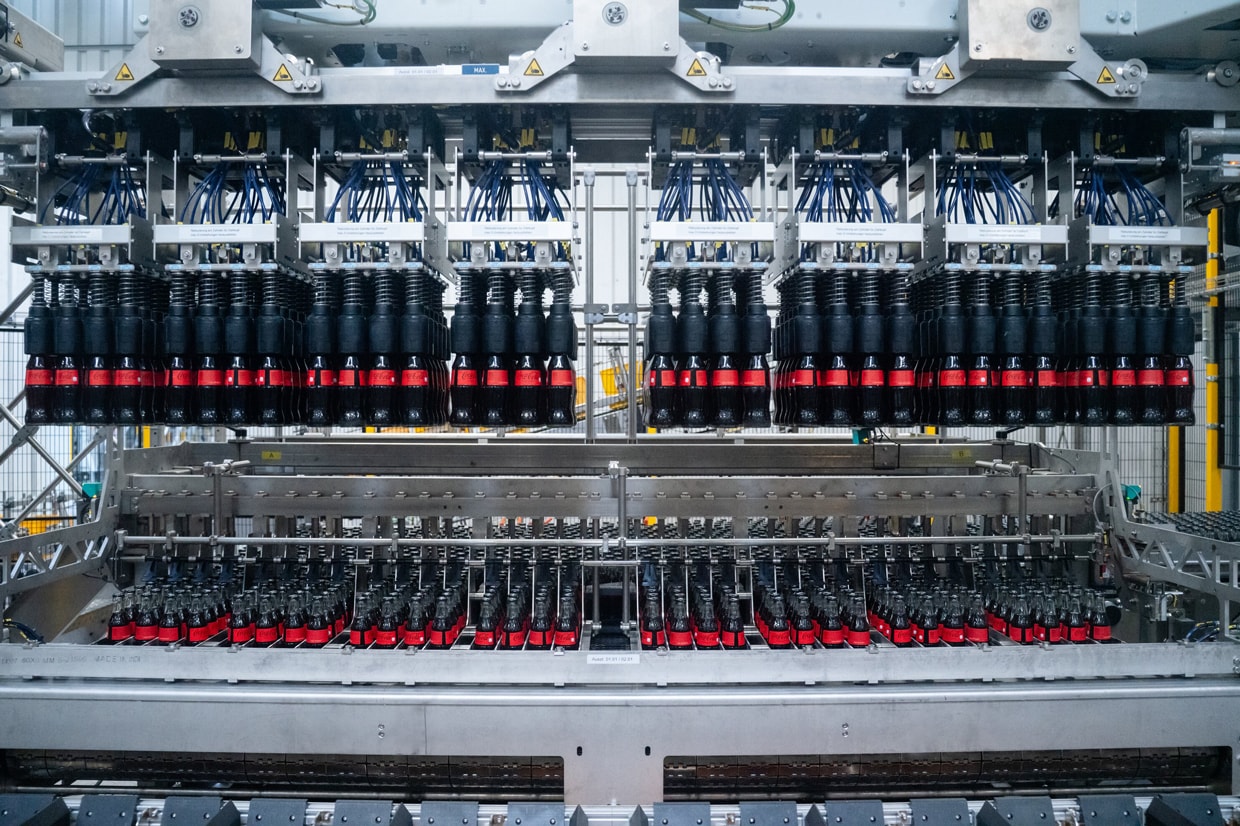

Sustainability plays a central role, not only when it comes to logistics. CCEP DE also makes it a priority for its packaging, employing a diverse range of packaging solutions that are tailored to the situation at hand. “You can’t say that glass or PET is more sustainable in and of itself. It always depends on the context,” explains Plant Manager Francis Driessen. “Our goal is to offer the right solution to meet every need.” That being said, glass is definitely trending. In northern Germany, more and more consumers are choosing returnable bottles made of glass when they buy Coca-Cola, Fanta or Mezzo Mix.

Our goal is to offer the right solution to meet every need.

Francis DriessenPlant Manager at Lüneburg

Francis DriessenPlant Manager at Lüneburg